14

English

Cutting Head

The Nylon cutter is equipped with a nylon string cutting head.

Do not use any other type of cutting device with this model.

WARNING

Use only cutters specified or recommended by

Manufacturer. Wear safety goggles, shoes, gloves, and

protective clothing whenever operating.

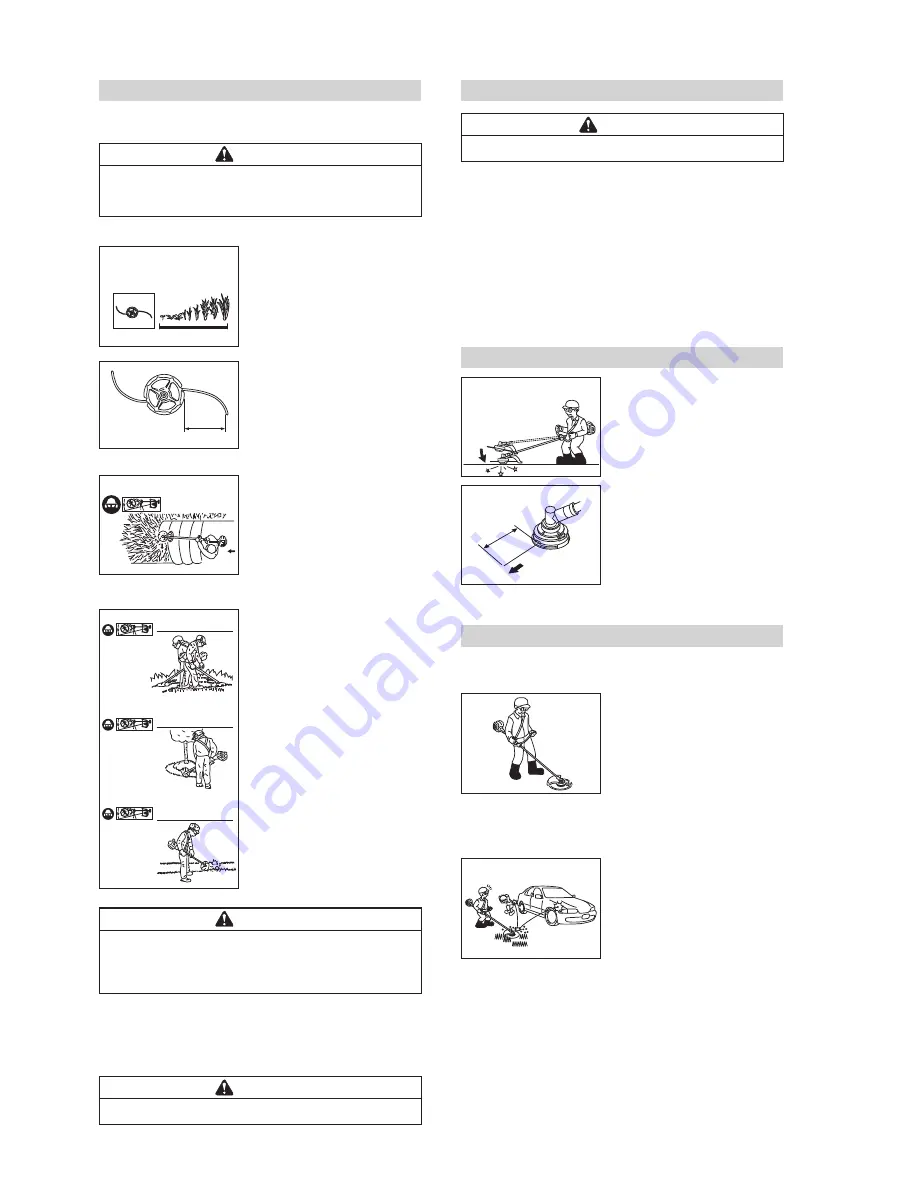

Nylon Cutter

Pull out the nylon cord from the

cutting head by 10-15 cm.

Working methods

Since cutting head rotates in the

left direction (as seen from the

top), it is more efficient to mow

grass from right to left.

NOTE

○

The left trimming methods

done with nylon cutting head.

WARNING

In case the cutting head hits anything it should not

(stone or the like), stop the engine and check that the

head has no cracks. Always check that there is a safe

distance between the cutting device and your feet.

NOTE

○

If the cutting head is clogged or stuck with grass, weeds or

bushed, immediate stop the engine and remove it. Clean the

cutting head periodically.

WARNING

Do not use without Safety Guard.

Points to Check Before Operating

CAUTION

Be sure to check the following before starting the engine.

●

Check the cutting head for any deep scratches and cracks.

●

Check the cutting head for looseness. Tighten the head if it is

loose.

●

Push the button at the center or bottom of the cutting head

with a finger. Pull both ends of the nylon lines with both hands

and confirm that each end extends by about 2.5 cm with each

push of button.

●

Remove looseness by pulling both ends of the nylon lines.

Cut them to a length of 10 to 15 cm. Allow the line to be cut by

the blade on the cutter guard.

Increasing Cutting Line During Operation

●

Reduce the engine speed to

low and tap the bottom of the

nylon line cutter on the ground.

●

When the speed of the engine

is increased, the nylon line will

come out automatically.

●

If the nylon line does not come

out, repeat the procedures

above.

●

If the nylon line does not

come out even after repeating

the procedures above, wind

the nylon line by following

procedures in the Nylon Line

Replacement Section.

Safety Precautions

●

Do not use the nylon cutter for purposes other than cutting

grasses. This will protect you and others from accidents and

injuries.

●

Always wear protective clothing

and equipment, such as a

hat, protective goggles, long-

sleeved shirt, long pants,

gloves, and boots while

operating the cutter. This will

protect you from loose grass,

flying pebbles, etc.

●

Reduce the engine speed to low and tap the bottom of the

Nylon cutter.

●

Install the cutting attachment safety guard at the appropriate

part of the nylon cutter.

●

Pay attention to your

surroundings during operation.

Make sure to maintain a distance

of at least 15 m from anyone and

anything (e,g., pets and objects)

nearby.

This will protect you and others

from accidents and injuries

caused by loose grass and

flying objects.

●

Be sure to stop the engine before installing the scatter-

blocking cover or the cutting head, or inspecting the nylon

cutter/cutter parts. This will protect you and others from

accidents and injuries.

●

Do not touch the cutting head when the engine is running.

This will protect you and others from accidents and injuries.

●

Do not use a cutting head that has scratches or cracks. This

will protect you and others from accidents and injuries caused

by flying parts.

1

1

Nylon cutter:

For soft and low weeds

10-15 cm

MOW RIGHT

TO LEFT

SCYTHING

SCALPING

EDGING

Summary of Contents for DP-10

Page 2: ......