14

30. 06. 20. Document Number 671948

Nuaire |

Western Industrial Estate

|

Caerphilly

|

CF83 1NA

|

nuaire.co.uk

XBC+ with Ecosmart Classic (E) or No (N) Control

Installation Manual

5.2 Electrical Information

5.3 Using Test Button (ES Control Only)

The test button allows the individual blowers within the unit to be

checked for its operation. If the fan is running already, press the button

once to stop the fan, press again to switch on the fan.

The fan will

return to normal operation after 30 seconds.

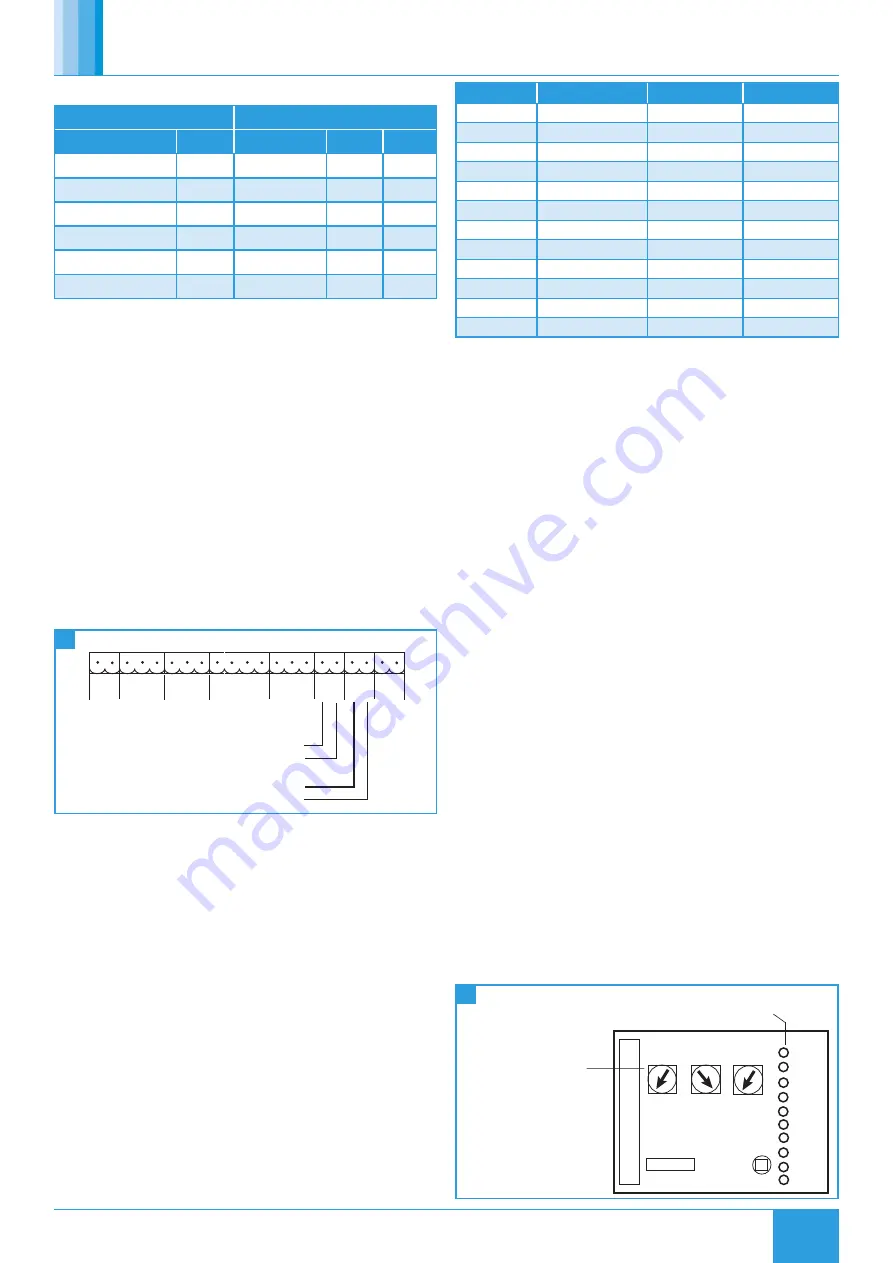

5.4 Supply & Extract Fan Speed Offset

This unit contains two fans and one control. Generally, the two

fans operate at similar speeds, but the control includes an “O

adjustment” for the slower fan (on the main circuit board).

If one of the fans needs to be run slower than the other, move the

control extract or supply signal plug into the o header (Figure 24).

Use the o ADJ pot (Figure 28, Figure 29 and Figure 30) to turn the

speed down.

Maximum turn down is 40%, i.e. reduce the drive signal to the slower

fan up to 40%. Note the response of the fan to the drive signal may not

be proportional at all signal values.

24

Supply & Extract Wiring

BMS

CO2 IN

SET

INV DRIVE

PIN

SUP

EXT

OFF

POINT

FAN

SET

FAN

Speed control signal

Speed control signal

for extract fan

for supply fan

5.5 LED Indication

PWR

GREEN: Power on & OK.

Standby

LED on when fan is not running.

Fan 1

GREEN: Fan 1 is running, RED: Fan 1 faulty.

Fan 2

GREEN: Fan 2 is running, RED: Fan 2 faulty.

Heating*

GREEN: Heating selected RED: Heating faulty.

Cooling*

Not applicable. See note.

Fault

LED on when a fault is present on unit.

Frost*

Not applicable. See note.

TX

LED on when the controller is transmitting data.

RX

LED on when the controller is receiving data.

* Note that the control panel is common to all the Ecosmart

products and will have indicators for functions that are not

available in this particular fan. However these indicators will not

be illuminated.

5.6 BMS Input Signals

The system’s response to a 0-10V DC BMS signal is given in the

following table.

Note the BMS signal will override any sensors and user control

connected in the system. The voltage tolerance is +/- 125mV and is

measured at the fans terminal.

5.7 Commissioning Settings

5.7.1 Maximum Airflow

•

Ensure the power supply is switched off and that a link wire is

connected from the supply L to the SL terminal.

Unplug all items connected to the ‘Net‘ connectors.

•

Switch on the power supply.

•

Wait for the fan to complete its self-test operation.

Measure the airflow using standard commissioning instruments at a

suitable point in the ductwork. If adjustment is required, rotate the pot

marked ‘MAX’ to obtain the desired airflow.

5.7.2 Minimum Airflow (Trickle)

•

Repeat the same procedure as for maximum airflow above but

without the link wire between supply L and SL terminal. Ensure the

trickle switch is in the ‘ON’ position. Adjustment must be made on

the pot marked ‘Min’.

The minimum setting (20% of maximum air flow)

must be

below the maximum setting; otherwise minimum setting will be

automatically set to be the same as the maximum.

5.7.3 Trickle Ventilation

Slide the ‘trickle’ switch 0 = Off, 1 = On. With ’trickle’ on and power

to unit, the fan will run at minimum speed until the switch live signal

activates it to boost.

5.7.4 Overrun Time

A switched live of 100-230V at terminal SL will activate the fan.

When the switched live signal is removed the fan will overrun for period

set by the dial ‘SL run on’ - adjust the desired overrun time between

1-60 minutes by rotating clockwise.

5.7.5 Air Off Temperature

The adjustment knob is located in the control pack and must be set to

the desired ‘air off’ temperature.

25

Commissioning Board

MIN

= Minimum speed

adjustment

MAX

= Maximum speed

adjustment

SL Run on = Switched Live

Run-On Timer

TRICKLE

adjustment

= Selects trickle

1 = selected

running: 0 = off,

TEST

= Test button

LED indicators

Min Max SL run on

Trickle

Test

0

1

Pwr

Standby

Fan 1

Fan 2

Heating

Cooling

Fault

TX

Frost

RX

Connector

Ecosmart

Ventilation Mode Cooling Mode* Heating Mode*

Local Control

0.00

-

-

OFF/ Trickle

0.25

-

-

Speed 1

0.50

0.75

1.00

Speed 2

1.50

1.75

2.00

Speed 3

2.50

2.75

3.00

Speed 4

3.50

3.75

4.00

Speed 5

4.50

4.75

5.00

Speed 6

5.50

5.75

6.00

Speed 7

6.50

6.75

7.00

Speed 8

7.50

7.75

8.00

Speed 9

8.50

8.75

9.00

Speed 10

9.50

9.75

10.00

Unit Without Electric Heater

Unit With Electric Heater

Unit Code

FLC

Unit Code

Fan FLC Heater

XBC10HA-(N/L)**

3.0 A

XBC10HA-E**

3.0 A

6.3 A

XBC15HA-(N/L)**

4.0 A

XBC15HA-E**

4.0 A

12.5 A

XBC25HA-(N/L)**

8.0 A

XBC25HA-E**

8.0 A

18.8 A

XBC45HA-(N/L)***

6.0 A

XBC45HA-E**

6.0 A

18.8 A

XBC55HA-(N/L)**

6.0 A

XBC55HA-E**

6.0 A

37.5 A

XBC65-HA-(N/L)**

6.0 A

XBC65HA-E**

6.0 A

37.5 A