2

30. 06. 20. Document Number 671948

Nuaire |

Western Industrial Estate

|

Caerphilly

|

CF83 1NA

|

nuaire.co.uk

XBC+ with Ecosmart Classic (E) or No (N) Control

Installation Manual

1.2 Important Information

This manual contains important information on the safe and

appropriate assembly, transport, commissioning, operation,

maintenance, disassembly and simple troubleshooting of the product.

While the product has been manufactured according to the accepted

rules of current technology, there is still a danger of personal injury or

damage to equipment if the following general safety instructions and

the warnings contained in these instructions are not complied with.

•

Read these instructions completely and thoroughly before

working with the product.

•

Keep these instructions in a location where they are accessible

to all users at all times.

•

Always include the operating instructions when you pass the

product on to third parties.

1.3 Personal Protective Equipment

The following minimum Personal Protective Equipment (PPE) is

recommended when interacting with Nuaire product:

•

Protective Steel Toed Shoes -

when handling heavy objects.

•

Full Finger Gloves (Marigold PU800 or equivalent) -

when

handling sheet metal components.

•

Semi Fingerless Gloves (Marigold PU3000 3DO or equivalent)

- when conducting light work on the unit requiring tactile

dexterity.

•

Safety Glasses

- when conducting any cleaning/cutting operation

or exchanging filters.

•

Reusable Half Mask Respirators

- when replacing filters which

have been in contact with normal room or environmental air.

Nuaire would always recommend a site specific risk assessment by a

competent person to determine if any additional PPE is required.

2.0 INTRODUCTION

The information contained in this document provides details of

installation, operation and maintenance for installers and users of the

XBOXER XBC Supply and Extract Ventilation Unit with Heat Recovery.

This supply and extract air handling unit range comprises an

combination of high efficiency centrifugal fans with EC motors, a

Counterflow design plate heat exchanger, filters, optional heaters

(LPHW and Electric) and a casing with high mass acoustic treatment.

A range of matched, close coupled attenuators with a similar

construction method to that of the unit is available. The attenuators

can be flipped for positioning on the left or right of the fan unit

(Figure 1) allowing flexibility for duct layout.

Attenuators are available in 1050, 1250 and 1600mm lengths and a

matching attenuator flange is attached to the fan unit.

General information regarding performance and specifications for

the equipment may be obtained from our Technical Literature, and/or

project specific documentation.

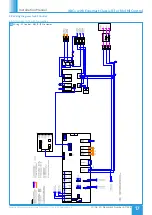

XBC Unit

Room Side Extract / Supply Attenuator:

1050 / 1250 / 1600mm long (optional)

and Pump *

Access to Intake Filter /

Fan / Condensate tray

Atmospheric side Intake / Discharge Attenuator:

1050 / 1250 / 160

0 mm long (optional)

Access to Controls *

Access to Coil bleed and drain /

Valve / Valve Actuator /

Electric Heater Elements *

Access to Extract FIlter / Fan *

Duct Connection Blanking Panel

Attenuator/Flange

connector

connector

Attenuator/Flange

*Unlock an access panel by inserting a flat head screwdriver

into the locking latch and turning anti-clockwise (1/4 turn).

Note: Bottom access unit (BA) Filters cannot be accessed

from the side of the unit.

1

Unit Layout Overview