9

nuaire.co.uk

029 2085 8400

13. 03. 19. Document Number 671188

Installation and Maintenance

Ecosmart Boxer Air Handling Units

4.1 Connections

4.1.1 Mains Connections

Mains cables should be suitably sized and terminated at terminals

shown on the appropriate diagram.

Where units form part of a system it will be necessary to install

and connect mains wiring between controls and devices such as

heat exchangers and motorised dampers - refer to the relevant

section of this document.

Where units are supplied in modular sections, sizes 3 to 7, it will

also be necessary to install and connect mains wiring between

sensors and actuators. Extension of the cable looms may be

required.

4.1.2 Control Connections

Net - the 4 IDC plug-in connectors are

provided for the connection of compatible

sensors, manual controls and for linking the

fans together under a common control.

If more than 4 connections are required, the

junction box (product code ES-JB) should be

used (see data cable installation).

Where units are supplied in modular sections, sizes 3 to 7, or as part

of a system it will also be necessary to install data cable (supplied)

between Ecosmart controls and from Ecosmart sensors and heat

exchanger etc.

4.1.3 Switched Live (SL) Terminal

A signal of 100 - 230V AC will

activate the fan from either its off

state or trickle state (see setting to

work-trickle switch). When the SL

is disconnected the fan will

over-run (see setting to

work-timer adjustment).

Do not take this signal from an

isolating transformer.

4.1.4 Damper Connections

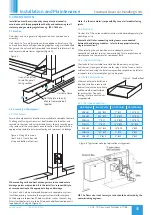

4.1.6 Data Cable Installation

A 4-core SELV data cable is used to connect devices. Do not run data

cable in the same conduit as the mains cables and ensure there is

a 50mm separation between the data cable and other cables. The

maximum cable run between any two devices is 300m when it is

installed in accordance with the instructions.

Please note that the total data cable length used in any system

must be less than 1000m. Keep the number of cable joints to a

minimum to ensure the best data transmission efficiency between

devices.

4.1.7 Maximum Number of Devices

The maximum number of devices (including fans) that can be

connected together via the cable is 32, irrespective of their functions.

4.1.8 Other Low Voltage Cables

Follow the basic principle

(as Data cable installation)

. Keep the cable

run as short as possible and less than 50 metres.

4.1.9 BMS Input Signals

The BMS connection is made with a plug-in connector

via the socket (Figure 22). To ensure the connection

is made only by suitably qualified and authorised

personnel the plug is not supplied.

It is available from R S Components, Part No. 403-875

or Farnell, Part No. 963-021.

4.1.5 Volt Free Relay Contacts

Note that the volt free contacts are not

fused. If these are used to power any external

equipment, the installer must provide

adequate fusing or other protections.

These contacts are rated at 5A resistive, 0.5A

inductive.

Run Connections

= Contacts closed when fan is running.

Fault Connections: No fault

= Contacts closed.

Fault

= Contacts open.

Heat Demand

= Contacts closed when heating selected.

Cooling Demand

= Contacts closed when cooling selected.

Do not use this contact to switch compressors directly.

Frost Alarm

- Contacts closed when air off temperature is 4°C or

below. Fan shuts down, valve opens and the heat demand contacts

activated.

DX1

- contacts close when stage 1 of DX coil selected.

DX2

- contacts close when stage 2 of DX coil selected.

OP

- 230V 50Hz 1A max supply to open the damper

CL

- 230V 50Hz 1A max supply to close the damper

N

- Neutral supply to damper

RET

- 230V ac return signal from the damper limit switch indicates the

damper has reached its operating position. If the return signal is not

present, the fan will wait for 1 minute before starting.

Note: If a damper is not fitted, connect a link wire from OP to RET. This

will cancel the delay.

Figure 16. ‘Net’ connection

for Ecosmart devices.

Figure 20.

Figure 22.

Figure 21.

Figure 17.

Figure 18. Drive Open/

Spring Close.

Figure 19. Drive Open/

Drive Close.

SL

L

E

N

Remove link if switched live signal, an

enabler or BMS signal is connected

Mains connection

230V 50Hz 1PH

OP

S4

S6

230V

motor

230V

motor

A fan starting delay

of 1 minute is

imposed to enable

the damper to

open.

To override the

delay fit a link here.

A fan starting delay

of 1 minute is

imposed to enable

the damper to

open.

To override the

delay fit a link here.

All wiring is 1PH 230V 50Hz

All wiring is 1PH 230V 50Hz

White

Brown

Blue

2

1

CL

N

RET

OP

CL

N

RET

RUN

Run signal

Fault signal

FAULT

Cooling

Demand

Signal

Frost

Alarm

Signal

Signal for

DX1 coil

if fitted

Signal for

DX2 coil

if fitted

Connect to inlet

sensor after unit

is assembled

Outlet

sensor

Inlet

Sensor

BMS

0-10V

10V

IMPORTANT

Reversal of the BMS connection will damage the control.