11

nuaire.co.uk

029 2085 8400

13. 03. 19. Document Number 671188

Installation and Maintenance

Ecosmart Boxer Air Handling Units

6.0 MAINTENANCE

6.1 Maintenance Intervals

The first maintenance should be carried out three months after

commissioning and thereafter at twelve monthly intervals. These

intervals may need to be shortened if the unit is operating in adverse

environmental conditions, or in heavily polluted air.

6.2 Lubrication

Motors are fitted with sealed for life bearings and do not require any

lubrication.

6.3 General Cleaning and Inspection

Clean and inspect the exterior of the fan unit and associated controls

etc. Remove the access panel from the fan unit. Inspect and, if

necessary, clean the fan and motor assemblies and the interior of the

case. If the unit is heavily soiled it may be more convenient to remove

the fan / motor assemblies. If Nuaire controls and or remote indicators

are fitted, remove the covers and carefully clean out the interiors as

necessary. Check for damage. Check security of components. Refit the

access covers.

6.4 General

Check that all fixings are tight. Check sealing strips around the fan

outlets are tight up against the bulkhead. Check that duct connections

are not leaking.

6.5 Filters

Disposable filters should be changed when fully dust laden. Washable

filters should be removed and washed in mild detergent, flushed with

clean water and allowed to dry before refitting.

6.6 Cleaning Control Box and Sensors (if fitted)

Remove covers and carefully clean out interiors as necessary. Check for

damage and security of components. Refit covers.

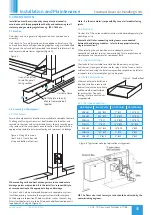

6.7 Adjusting Drive Belt Tension (Sizes 3-6)

To check the correct tension of a drive belt, apply a force at right angles

to the centre of the belt span sufficient to deflect the belt 16mm for

every metre of span length (Figure 26). The force required to deflect the

‘V’ belt should be from 0.5kg to 0.8kg.

6.8 Changing a Drive Belt

To replace a belt, remove the two bolts from the motor mounting

furthest from the fan and slacken the remaining two bolts. Lift the

motor plate and remove the belt. Replacing the belt is the reverse of

this procedure.

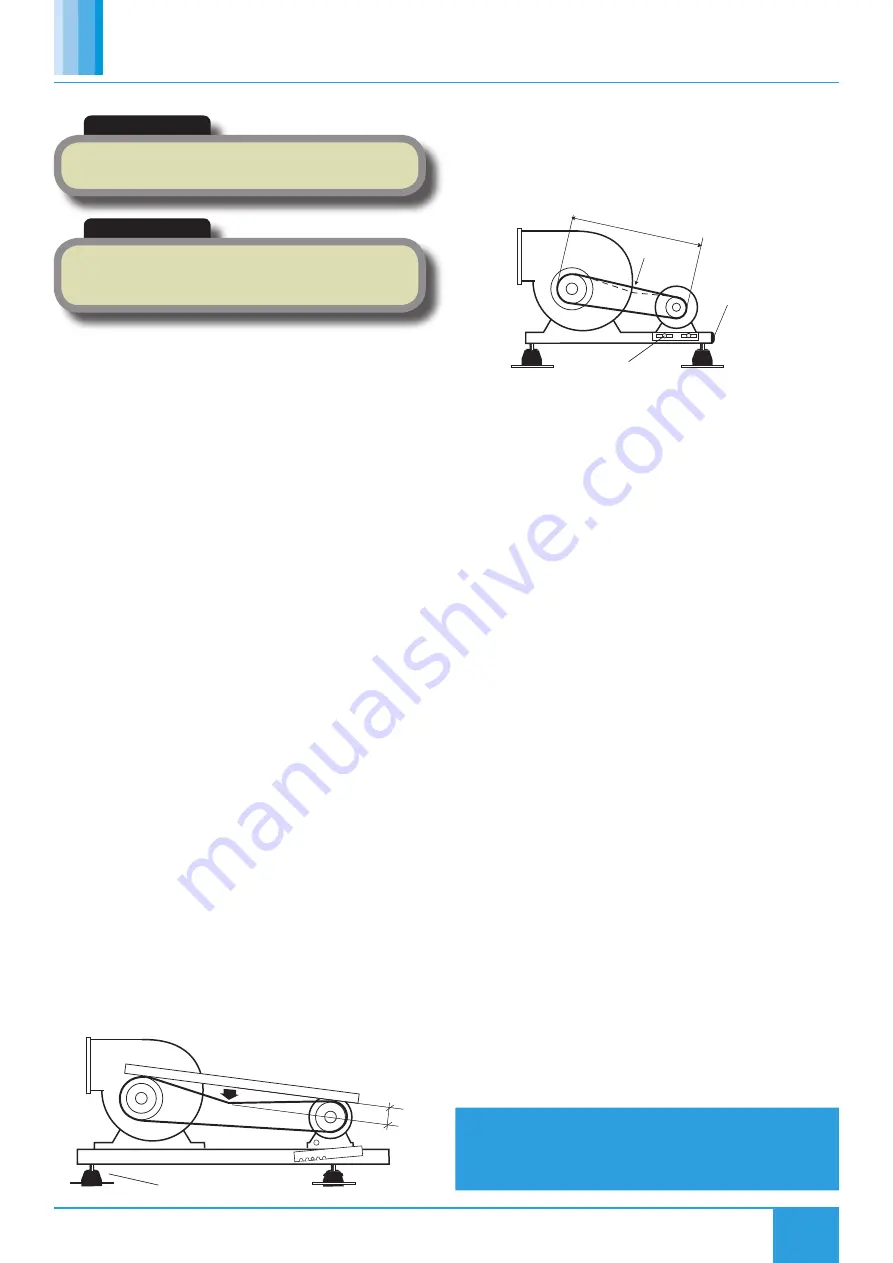

6.9 Adjusting Drive Belt Tension (Size 7)

All belt drive units incorporate belt tensioning devices. To adjust the

belt tension, slacken the pinch bolt on the sides of the motor plate.

Turn the adjusting bolt clockwise to tighten the belt and counter

clockwise to loosen it. The drive should be tensioned until a slight bow

appears in the slack side of the ‘V’ belt when running under load.

6.10 Checking Belt Tension

•

Measure the span length (Figure 27).

•

At the centre of the span, apply a force at right angles to the belt

sufficient to deflect one belt 16mm for every metre of span length

(Figure 27). The force required to deflect the ‘V’ belt should be

from 0.5kg to 0.8kg.

•

Tighten the pinch bolts.

6.11 Replacement of Parts

Should any component need replacing Nuaire keep extensive stocks

for quick delivery. Ensure that the unit is electrically isolated, before

carrying out any work.

When ordering spare parts, please quote the serial number of the unit

and the ARC number of the purchase if possible

(This information will

be available on the fan label).

7.0 WARRANTY

The 5 year warranty starts from the day of delivery and includes parts

and labour for the first year. The remaining period covers replacement

parts only.

This warranty is void if the equipment is modified without

authorisation, is incorrectly applied, misused, disassembled, or not

installed, commissioned and maintained in accordance with the details

contained in this manual and general good practice.

The product warranty applies to the UK mainland and in accordance

with Clause 14 of our Conditions of Sale. Customers purchasing from

outside of the UK should contact Nuaire International Sales office for

further details

8.0 AFTER SALES ENQUIRIES

For technical assistance or further product information, including spare

parts and replacement components, please contact the After Sales

Department.

IMPORTANT

Before commencing work, make sure that the unit and Nuaire

control are electrically isolated from the mains supply.

IMPORTANT

An Inverter is used to provide speed control. When the fan is

isolated, allow 5 minutes for the capacitors in the inverter to

discharge before commencing any work on the unit.

Anti-vibration moutings

Deflection

Figure 26. Adjusting the drive belts (Sizes 3-6).

Span

Force

Adusting Bolt

Pinch Bolt

Figure 27. Adjusting the drive belts (Size 7).

Telephone 02920 858 400