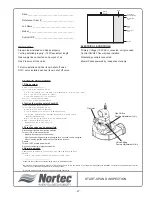

START UP PROCEDURE

Also see Startup Sheet on page 27.

Prior to filling the unit, it is necessary to ensure

that no dirt or dust has accumulated in the control

compartment. If necessary, clean this area to prevent

contaminants from being drawn into the combustion

blower. All water, gas, electrical and venting

connections must be properly completed and tested

before commissioning the unit.

FILLING THE SYSTEM (approximate time to fill: 1

hour)

Before the GH unit will initiate combustion it must

be filled with water to the low level setting of the water

level controller. (Refer to water level control). To fill

with water, turn the gas supply off and switch the unit

on at the power switch. After turning the unit on, give it

a call for humidity to start the fill cycle. The unit will fill

automatically until the low water level is reached and

then trial for ignition will begin. After three tries the

ignition module(s) will lock-out. Leave the unit

switched on until the fill sequence is complete. Then

switch off the power and proceed with the ignition

safety shut-off test.

TESTING THE IGNITION SAFETY SHUT-OFF

The ignition system safety shut-off must be tested

by conducting the following method of test:

1.

With the gas supply off, turn power on.

2.

Blower pre-purges for 30 seconds.

NOTE:

On multi-blower models, it is

necessary to wait for all blowers to cycle.

3.

After seven seconds the gas valve is

energized for four seconds, then

de-energized. After three trials for ignition

(complete with pre-purge) the unit goes into a

safety lockout.

4.

Manually re-open the gas supply. No gas

should flow to the main burner. End of test.

5.

To reset the system, momentarily shut off

power switch, then turn it back on again. After

a pre-purge the igniter will start to heat up and

normal operating cycle will occur as described

in the IGNITION SEQUENCE.

PRE-PURGE OF GAS VALVE AND MANIFOLD

1.

Disconnect all igniters from ignition modules.

2.

Turn unit on at main power switch. The

blower will pre-purge for 30 seconds. After 7

seconds the gas valve will energize for 4

seconds, then de-energize. After 3 tries the

ignition module will go into safety lockout.

3.

Repeat this minimum 2 times in order to

ensure no air is left in the line.

4.

Turn unit OFF at main power switch.

5.

Re-connect all igniters to ignition modules.

- 17 -

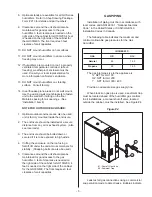

GHB

and

GHP

Water Hardness

Inspection Interval

Blowdown Potentiometer Setting

(located on the electrical panel behind the locked door)

All GHB and GHP Models

<4 grains

Annual

Between low & midpoint

4-10 grains

Semi-Annual

Between midpoint and maximum

>10 grains

Bi-monthly

Maximum

GHMC

Water

Hardness

Inspection

Interval

Blowdown DRN1 Setting

GHMC 100

GHMC 200

GHMC 300

GHMC 400

<4 grains

Annual

2

2

3

8

4-10 grains

Semi-Annual

3

4

6

10

>10 grains

Bi-monthly

4

6

8

12

*Refer to GHMC instruction manual for programming instructions.

Summary of Contents for GH 100

Page 43: ... 39 ...