17

2. Brake system

2.1 Summarize

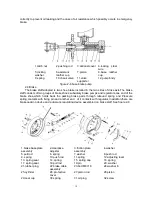

Brake system,Being Two-front-wheel internal expansion oil pump type,consists of brake

paddle,brake base pump and wheel brake staff

2.2 Brake paddle

The construction of brake paddle is illustrated in figure 2-7.The paddle transfers the stamp

force exerted by the pushing rod of brake base pump into the pressure of brake oil

1. brake oil cup

2. brake support

3. brake sensor

4. bolt

5. brake pedal

6. brake pump

figure 2-7 brake paddle assembly

2.3 Brake base pump

(

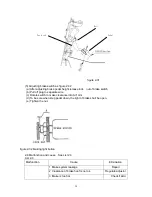

figure 2-8

)

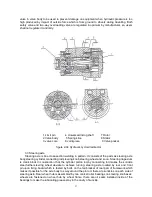

Base pump consists of a valve support,a one-way-valve,a rebound spring and base leather

cup,piston,assistant leather cup.The end of the base pump is fixed with lock washer and lock steel

wire,And the outside of it is protected with rubber dust preventing cover.The base pump works

under the assistance of pushing rod by operating brake paddle,Step down the brake paddle,the

rod pushs the piston,the brake fluid flow back to oilcan through oil return hole until the base leather

cup plugs the oil return hole.After the base leather cup push over the oil return hole,the brake fluid

of the front cavity of base pump is compressed and open the one way valve and through brake

pipeline flow into subsidiary pump.Then,the piston of each subsidiary pump pushes out to make

the brake shoe wearing piece get contact with the brake drum,and finally stop the truck or make it

slowdown. Now,the back cavity is supplied with the fluid by the brake fluid from oil return hole and

oil-in hole.Release the brake paddle,the piston is push backward by the brake shoe rebound

spring,at the same time,the brake fluid in each subsidiary brake pump is compressed by the

rebound spring.Which makes the brake fluid flow back to base pump through one way valve,the

piston returns back to initial position,the brake fluid in base pump flow back to oilcan through oil

return hole,one way valve pressure is adjusted in proportion to the residual pressure in brake

pipeline and subsidiary brake pump,the leather cups in subsidiary pump should be placed