Use and Maintenance Manual model “H14 V SHAPE”

5

ENGLISH

ENGLISH

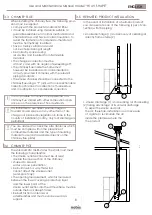

• The product can be used by children over

8 years of age and people with reduced

physical, sensor or mental capacity, or without

experience or the necessary know-how, provided

they are supervised, or have received

instructions on the safe use of

the appliance and have understood the dangers

involved. Children must not play with

the appliance.

• Cleaning and maintenance intended to be

carried out by the user must not be carried out

by children without supervision.

• Do not dry washing on the

the product.

• Fuel and flammable materials must be

kept a necessary distance from the product.

Danger of fire.

• The product must be electrically connected

to a system equipped with a sufficient ground

system.

• In the event of a fault on the switch on system, do not

force switch on using flammable

materials and consult an authorised technician.

• Installation is forbidden in small rooms, bedrooms,

surroundings with explosive atmospheres, etc.

1.6 LEGAL WARRANTY

The user, to benefit from the legal warranty,

must strictly comply with the provisions

indicated in this manual. In particular:

• always work within the use limitations of the product;

• always carry out routine maintenance;

• authorise people to use the machine with proven

capacity, attitudes and who are adequately trained

for the purpose;

• use original spare parts and specifically

for the appliance model.

It is also necessary to provide a:

• fiscal receipt with the purchase date;

• a certificate of compliance issued for installation

by authorised staff.

Non-compliance with the provisions contained in this

manual will imply immediate

expiry of the warranty on the product and on

any spare parts assembled

later.

1.7 EXCLUSIONS FROM THE WARRANTY

The warranty excludes all malfunctions and/or dam-

age to the appliance resulting from the following

causes:

• damage caused by transport and/or movement;

• all parts resulting as being faulty due to

negligence or careless use, wrong

maintenance, non-conforming installation

with that specified by the manufacturer

(refer to the installation and use manual

supplied with the appliance);

• further damage caused by wrong intervention

by the user in an attempt to solve the

initial fault;

• aggravated damage caused by further use

of the appliance by the user once

the defect was noted;

• in the presence of a boiler, any corrosion,

scale or breakages caused by stray

current, condensate, abrasion or acidity in the

water, scale removal treatments carried out

improperly, no water, sludge or

limescale deposits;

• inefficiency of the chimneys, chimney flues or parts of the

system on which the appliance depends;

• damage caused by tampering with the appliance,

atmospheric agents, natural disasters, vandalism,

electrical discharge, fire, faulty

electrical and/or plumbing system.

The following are also excluded from the warranty:

• parts subject to normal wear such as gaskets,

glass, coverings and grates in cast iron, painted,

chrome-plated or gold-plated parts, handles and

electrical

cables, lights, switch on resistor, indicator lights,

knobs, all parts that can be removed from the

fireplace (e.g. refractory, brazier);

• colour variations of painted and ceramic parts,

as well as the ceramic cracks since they are

natural features of the material

and use of the product;

• masonry works;

• parts of the system (if present) not supplied by

the manufacturer;

Any technical intervention on the product

to eliminate the aforementioned defects or resulting

damage should therefore be agreed

with the Technical Support Centre, which

reserves the right to access or refuse the relevant job and

in any case they will not be carried out under

warranty, but rather Technical Support will provide the

possible conditions to specifically agree upon

and according to rates in force for the works to carry out.

The user will also be responsible for the expenses which will

be necessary

to resolve any wrong technical intervention, tampering

or however damaging factors for the appliance

not attributable to the original defects.

Notwithstanding the restrictions imposed by legislation

and regulations,

every warranty to contain atmospheric and acoustic pol-

lution is also excluded.