Use and Maintenance Manual model “H14 V SHAPE”

32

ENGLISH

This paragraph describes the behavior of the

remote control when a system diagram different

from the standard one (that is, when the device is

operating directly with the heating system) is activated.

Activating such diagram (operation reserved for a

specialized technician), while maintaining the same

menu functions, the screen adapts to the display of

all connected utilities, such as the DHW storage tank

temperature or the technical H

2

O storage tank.

13 ADVANCED HYDRAULIC DIAGRAMS

In case the type of system diagram designed requires

the management of the 3-way valve (diagram 1

and 3), it is necessary to purchase an optional kit at

a Nobis authorized sales point or technician.

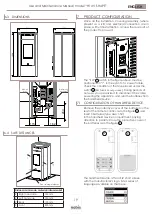

13.1 DIAGRAM 01

(DHW TANK + HEATING)

The following diagram can be used when a boiler

without a plate heat exchanger is in use and the

User wants to buy an accumulator (boiler) to be con-

nected to the circuit, in order to produce domestic

hot water. In this kind of circuit, the room temperature

is managed by the remote control which, having a ra-

dio connection, acts as a remote chronothermostat.

STAND-BY SCREEN

1

2

It shows boiler water actual temperature as detected

by the probe. Moreover, temperature settings – edi-

table by using – can be shown by pressing

scroll buttons.

Any change is confirmed either automatically - within

3 seconds from the last change – or by pressing

button. An acoustic signal will confirm the change.

OK

1

2

It shows the DHW storage temperature as detected

by the probe. Temperature settings – editable by

pressing – can be shown by pressing scroll

buttons. Any change in temperature settings is confir

-

med either automatically - within 3 seconds from the

last change – or by pressing button. An acoustic

signal will confirm the change.

OK

The operation is the same as the one described in the

basic diagram, with the only difference that, here the

product exchanges directly in the DHW storage (prio-

rity); when the set temperature is reached, the three-

way valve changes its position and the appliance

begins to exchange in the heating circuit. From this

moment on, heating can be managed by using the

remote control to set the room temperature as well

as H

2

O temperature (see diagram 00 operation re-

lated to modulation, eco stop, etc.). The three-way

valve redirects itself to the DHW storage when:

- it is required by the storage tank itself;

- it is required by the flow switch

(optional, if connected)

From ECOSTOP or H

2

O STANDBY status, the product

restarts considering heating or DHW accumulator

settings.

By setting SUMMER mode, the three-way valve

remains fixed, allowing heat produced by the

appliance to be transferred only inside the DHW

storage tank. As soon as this condition is reached,

the product switches to ECO STOP mode.

The DHW storage is managed by the appliance thanks

to a contact or immersion probe (not provided) to be

connected on the back side of the product.

The new stand-by screen is shown below.

To go back to the STAND-BY screen, press

button

repeatedly

The turbulators are activated automatically each

time the appliance is switched on/off and by means

of a timer during operation. It never occurs when the

machine is not active.

When you pass from one screen to another, you

display the following screen for a few seconds:

GENERAL INFORMATION NOTE:

This screen indicates the handheld device is trying

to communicate with the appliance, a useful

operation to recover information to display to the

end user.

If communication is absent, the writing FIELD followed

by a number appears. In this case, simply approach

the appliance to re-establish

communication.

1

2

1

2