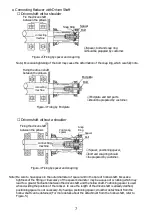

2 Attaching Chains, V-Belts, Gears, etc.

①

②

③

・

・

・ The chain is too loose.

・

3 Attaching and Detaching a Driven Shaft to/from AF3S Type Hollow Shaft

●Attaching a Driven Shaft to the Reducer Hollow Shaft

①

②

③

④

⑤

Tensions for belt and chain

are correct.

The tension of the Chains/V-Belts and the coupling of the gear must be perpendicular to the

center of the shaft.

In any connection, connect the units precisely, so that the center of the shaft of the reducer

and that of the other equipment are parallel.

The positions of pulley and

sprocket are also correct.

In case impact does not apply in the uniform load, loose fit is recommended for the fit tolerance

of driven shaft. In case shock load or heavy radial load is applied to the shaft, the fit should be

tighter. The bore of the hollow shaft is machined to conform to "JIS H8" tolerance.

The length of the driven shaft and the fixing key are recommended to be within the area

where "H8" tolerance for the fixed side bore is required.

It is recommended to minimize the fluctuation of the driven shaft below 0.05 at the shaft

edge. The greater fluctuation may give harmful effect to the reducer.

The sprocket is positioned

in the reverse direction so

that the load point moves

to the shaft edge.

When attaching, be sure to smear extreme pressure agent (molybdenum disulfide, etc.) on the

surface of driven shaft and the bore of the hollow shaft to avoid seizing, and insert the reducer

to the driven shaft.

If the fitting is too tight, for smooth insertion, knock on the hollow drive shaft end gently with

plastic hammer. In this case be sure not to hit the casing. Smoother insertion can be obtained if

you prepare jigs shown in the figure below.

Tension of the V-Belt: Excessive tensioning may result in damage to the bearings of the shaft.

Tension of the Chain: Excessive tensioning may result in damage to the bearings of the shaft. If

the chain is installed loosely, shock load will occur when the drive shaft starts rotation, and this

can result in damage to the reducer and the other equipment. Therefore, adjust the tension of

the chain properly.

Driven Shaft

Key

Area where the tolerance

of the bore should be

within "H8"

Hollow

Shaft

Area where the tolerance

of the bore should be

within "H8" (fixed side).

Spacer

Nut (Output shaft can be

inserted by tightening

the nut.)

Bolt

Bearing

Oil Seal

Figue-1

※Spacer, nut, bolt, key and

other parts for bearing should

be prepared by customer.

Connecting

machine

sprocket

Connecting

machine

Proper Way of Use

Bad Example

6