3.Specifications

①Motor Specifications

●

Capacity(kW)

Item

Motor Type

Rated Current

(A)

Ambient Temperature (℃)

Protection

②Brake Specifications

Capacity(kW)

Item

Voltage

(±10%)(V)

Current

(at 20℃)(A)

Power

(at 20℃)(W)

4.Maintenance and Lifetime

4-1.Maintenance and Lifetime

●

●

4-2.Method for Brake Gap Adjustment

1

2

3

30

(mm)

200

2.0

Maximum Extension

Distance

0.36

0.2kW

0.1kW

0.2kW

0.4kW

0.4kW

Blushless DC Motor

0 to 40℃

0.6

0.9

0.1kW

0.75kW

3.8

24

0.58

Totally enclosed non-ventilated (IP65)

0.57

0.95

1.76

3.43

13.9

0.58

13.9

1.05

20.6

0.75kW

8.6

(N・m)

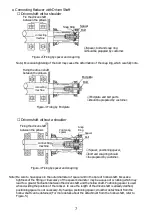

■Attaching direction of the

castellated nut.

The life of oil seal may vary according to the condition of use. Therefore replacement

may be needed even within 10,000 hours use.

The Rated Current described in the following table is a reference value without the

gearhead. (motor unit only)

"Power-off, Brake-on" Type

(Spring Close)

(m)

All models use grease lubricant, without needing replacement or replenishment. The

gear motor has been designed for an approximate use life of 10,000 hours.

Length of Motor

Lead Wire

Brake Type

Holding Torque

(at motor shaft)

Danger

After inspection and adjustment of the gap, do not

operate the motor with the brake cover open. Failure to

observe this warning may cause wind-in and physical

injury.

When adjusting the gap, be sure to disconnect the motor

from the power source. Failure to observe this warning

may cause physical injury. In the event of the castellated

nut removed, be sure to attach it in the right direction.

Attaching in the wrong direction may cause damages. For

the right attaching direction, refer to the attaching

direction of the castellated nut shown right.

After inspection and adjustment of the gap, be sure to

confirm if the brake functions properly by turning the

switch on and off. Failure to observe this warning may

cause accident by falling or run out of control.

11