5.Troubleshooting

Improper installation or slacked

bolts.

Foreign substances or oil are

adhered to the friction disk.

Disconnection or short circuit of

brake coil.

When the defective operation is found, please check the cause and take measures

according to the following points.

Disconnection of motor power

cable.

Disconnection or poor contact of

motor signal cable.

Motor power cable is too long.

Continued noise - defective

bearing, worn out gear.

Damaged switch.

Life of the friction disk.

Broken gear, shaft or bearing.

Worn out gear.

Repair or replace the switch.

Repair at authorized factory.

Remove foreign substances.

Excessive moment of load inertia.

Larger brake gap.

Poor contact of switch.

Repair at authorized factory.

Reduce the load inertia.

Adjust the brake gap.

Repair at authorized factory.

Tighten the bolts.

Repair at authorized factory.

Worn out gear or bearing.

Reduce the frequency.

Repair at authorized factory.

Repair at authorized factory.

Repair at authorized factory.

Reduce the load.

Reduce the load.

Check the length and diameter

of power cable.

Overload operation.

Overload operation.

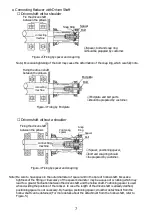

Troubleshooting

Cause

Repair at authorized factory.

Check the connection.

Check the connection.

Intermittent noise - damaged gear

or foreign substances inside the

motor.

Replace or repair the switch.

Abnormal noise

High frequency of start and stop.

Damage to bearings.

The motor does not

run even in the

unloaded condition.

The motor does not

run in the loaded

condition.

Abnormal rise in

temperature

Trouble

Excessive vibration

Brake does not work

Brake function is not

enough.

Motor does not run.

(Rotating speed does

not increase.)

Overheated motor.

Abnormal noise in

braking.

13