LLE14BRDA001A/E

7 - 59

6) Holding the stick by its handle, lightly touch the compound covered pad surface to the

rotating polishing wheel. The pad is gradually worn away.

Dress the wheel until the white surface of the pad wears away. Be careful not to let the

pad wear away all the way to the stick.

7) Apply the compound to the other side of the pad in the same manner as in Steps 5 and

6, and dress the polishing wheel again.

8) Press

to start the cooling water and wash the wheel.

With the water running, hold the stick by its handle and lightly touch the pad to the

polishing wheel to wash away any compound from the surface of the wheel.

9) Press

. The cooling water and wheel come to a stop.

10) After confirming that the wheel has stopped, remove moisture from the surface of the

polishing wheel by patting with a soft, dry cloth. Do not scrub the wheel roughly with the

cloth. Cloth fibers may remain, interfering with polishing.

11) When the surface of the polishing wheel dries, confirm that the compound is completely

washed away.

When the dried polishing wheel has a shine on its surface, the compound has been

washed away. Check the entire wheel. If the surface partly has no shine, the compound

remains. Press

to start the cooling water and wash the compound away.

<Safety beveling wheel>

* When safety beveling glass lenses frequently, dress the safety beveling wheel as well.

1) Press

. The safety beveling wheel

ASSY. comes out and the cooling water

runs.

2) Wet the dressing stick for finishing wheel

well with running water.

3) Press

to stop the cooling water.

4)

Lightly touch the dressing stick to the

wheel surfaces for safety beveling .

5) Release the dressing stick from the safety

beveling wheel.

6) Press

to start the cooling water and

wash the wheel surface away.

7) Press

. The safety beveling wheel is

stored.

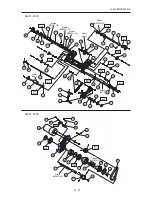

Safety beveling

wheel

Dressing stick

Summary of Contents for Le 1000

Page 1: ...PATTERNLESS EDGER Model SERVICE MANUAL June 2008 Pages in total 152 LLE14BRDA001A E...

Page 8: ...This page is intentionally left blank LLE14BRDA001A E 1 2...

Page 10: ...This page is intentionally left blank LLE14BRDA001A E 2 2...

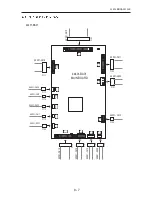

Page 19: ...LLE14BRDA001A E 3 9 3 3 Model Configuration...

Page 22: ...LLE14BRDA001A E 3 12 5 4 01 000000 9CVGT RTGUUWTG CZ M2C EU area only...

Page 28: ...LLE14BRDA001A 3 18...

Page 34: ...LLE14BRDA001A E This page is intentionally left blank...

Page 91: ...LLE14BRDA001A E 7 27 7 4 2 Parameter list of BL motor 40340 E066 E067 inverter User parameter...

Page 92: ...LLE14BRDA001A E 7 28 User parameter...

Page 93: ...LLE14BRDA001A E 7 29 System parameter...

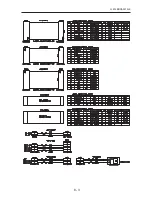

Page 126: ...LLE14BRDA001A E 8 2 8 2 Connector Cable...

Page 127: ...LLE14BRDA001A E 8 3...

Page 128: ...LLE14BRDA001A E 8 4...

Page 129: ...LLE14BRDA001A E 8 5...

Page 130: ...LLE14BRDA001A E 8 6...

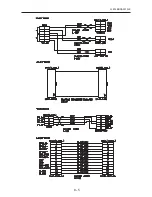

Page 131: ...LLE14BRDA001A E 8 7 44401 BA01 2 2 2 2 2 2 2 2 2 2 2 44401 BA01 MAIN BOARD 2 2 2...

Page 134: ...LLE14BRDA001A E 8 10 8 5 Grease MSDS 8 5 1 NIPPECO LLP...

Page 135: ...LLE14BRDA001A E 8 11...

Page 140: ...LLE14BRDA001A E 8 16 8 5 4 NBU15...

Page 141: ...LLE14BRDA001A E 8 17...

Page 142: ...LLE14BRDA001A E 8 18...

Page 143: ...LLE14BRDA001A E 8 19...

Page 144: ...LLE14BRDA001A E 8 20...

Page 145: ...LLE14BRDA001A E 8 21 8 6 Troubles and Measures...

Page 146: ...LLE14BRDA001A E 8 22...

Page 147: ...LLE14BRDA001A E 8 23...

Page 148: ...LLE14BRDA001A E 8 24...

Page 149: ...LLE14BRDA001A E 8 25...

Page 152: ...LLE14BRDA001A E 8 28 This page is intentionally left blank...