37

TRIPS - DIAGNOSTICS

POWERDRIVE MD2R Installation guide

4948 - 2017.11 / d

en

6 - TRIPS - DIAGNOSTICS

6.1 - Safety notice

The user must not attempt to repair the drive

himself, nor perform diagnostics other than those

listed in this section. If the drive malfunctions, please

contact your local technical support.

6.2 - Alarms

Alarms may appear during drive operation.

These alarms are for information only, in order to warn the

user: the drive continues to operate but may trigger a safetrip

if no corrective action is taken.

The HMI displays a page «active trips» where «ALARM»

appears at the top of the screen. All alarms shown on the

console or the configuration interface are listed in the

following table.

On the drive control board, 2 LED displays indicate alternately

"A.L." and a number that can be used to identify the alarm

by means of the table below (this number corresponds to the

value of parameter

10.97

).

Code

No.

Meaning

A.L.

1

to

4

User alarm 1 (

10.54

)

to

User alarm 4 (

10.54

)

6

Motor overload (

10.17

)

7

Drive overtemperature (

10.18

)

8

Microcontroller overoccupancy

9

Rectifier

10

Emergency operation (see menu 20)

6.3 - Tripping on a safetrip

If the drive trips, the drive output bridge is inactive, and the

drive no longer controls the motor.

When a trip is active, the LEDs present on the control board

display alternately "t.r." and a number that can be used to

identify the active trip (see left-hand column in the table

below). For trips numbered higher than 100, only the last 2

digits are displayed with a point displayed on both LEDs to

indicate the hundred.

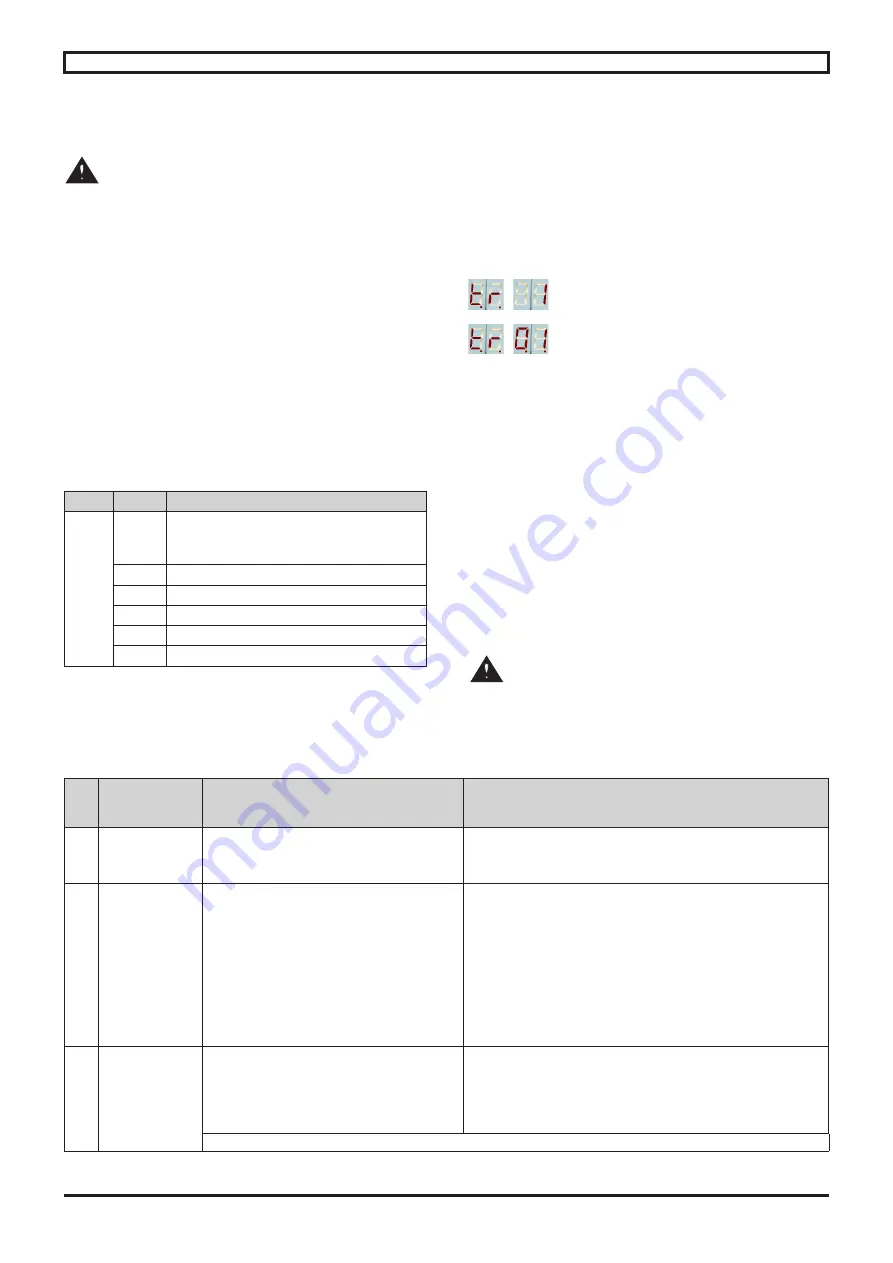

Example:

/

: indicates trip no. 1

/

: indicates trip no. 101

After consulting the table, follow the procedure below:

- Make sure that the drive is disabled (STO-1 and STO-2

terminals open)

- Isolate the drive power supply

- Carry out the necessary checks in order to eliminate

the reason for the trip

- Activate the STO-1 and STO-2 inputs to clear the trip

The HMI displays an active trip page, where "TRIP" appears

at the top of the screen.

All the trips indicated on the keypad or parameter-setting

interface are listed in the table below.

Nota : If motor inverter is disabled without any trips appearing

on the HMI, check the trips state on active rectifier (

18.24

).

The trip’s messages for parameter

18.24

are identical than

those explained in the board below

Opening and then closing the STO-1/STO-2 drive

enable terminals and clear the trip. If the Run FWD

or Run reverse terminal is closed at that time, the motor

may or may not start immediately, depending on the

setting of

Ctr.06

(

06.04

).

No.

Parameter-

setting interface

name

Reason for trip

Solution

1

DC UnderVolt

DC bus undervoltage

• Check the input fuses.

• Check the quality of the power supply (voltage dips).

2

DC over volt

DC bus overvoltage

• Check that the mains voltage is within the permitted

tolerance.

• Check the quality of the power supply (commutation

notches or transient overvoltages).

• Check the motor insulation.

• Check that the deceleration mode (

02.04

) is compatible

with the application.

• If an MD2-TF option is used, check its size, its wiring and the

state of the thermal relay.

3

Over current

Overcurrent at drive output

• Check the motor insulation.

• Check the motor cables (connections and insulation).

• Check the quality of the mains supply.

• Run power diagnostics.

This trip cannot be reset for a period of 10 seconds.