7

5.4 - Control box mounting

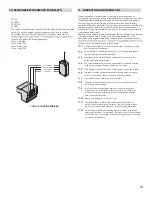

Main Power - This terminal block is for incoming 10-35VDC power only!

Connect wires to the main power terminal block. Positive of the power supply connects to the left terminal marked “+”. This

input should only be used with a power supply capable of supplying 10-35VDC at 20 amps.

SOLAR PANEL BATTERY

MAIN POWER

+ -

Mount the control box within 4 feet of the pivot arm. Use mounting hardware

capable of supporting the weight of the control box with the battery installed.

Do not mount the control box where the person using the push button on

side of the box can come in contact with the gate.

Set battery inside of control box with terminals toward the front (Do not use

any battery with side terminals).

FIGURE 5 - 6 CONTROL BOX MOUNTING

FIGURE 5 - 7 INCOMING POWER WIRING

5.5 - Incoming power wiring

Power input connections should be wired as follows:

Solar Panel

Connect wires to the solar panel terminal block. The positive wire of the panel connects to the left terminal marked “+”.

Note: If the panel is connected backwards a red LED will illuminate below the terminal.

If solar power is to be used it will be

necessary to program control board for STANDBY operation.

Battery

Connect wires to the battery terminal block. The positive wire of the battery connects to the left terminal marked “+”.

NOTE

If the battery is connected back-

wards a red LED will illuminate below

the terminal.

NOTE

If supply is connected backwards, a

red LED will illuminate below the

terminal. If supply is connected

properly, a green LED will illuminate.

Summary of Contents for Titan 912L

Page 2: ...TABLE OF CONTENTS...