19

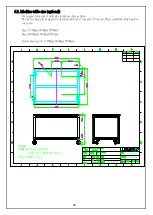

4.6. Continue press

Press and continue to set the job function and page description.

Used for press parameter test -

1. This functional test can be used when the connector manufacturer does not provide force standard parameters

for the press connector.

2. Set the force, distance, and speed of each connector before editing the recipe.

3. For engineering PCB board development test, can use the simple setting to do the job without using more steps

of recipe setting.

4. Quickly build press parameter into the edit recipe table.

For single program, small sample operation -

In the pressing of single or not many connectors, such as card or board production.

Connector Editor -

Create, query, modify connector data.

1. Mode selection -

1) Safety handle positioning status display box -

Prompt message whether the safety handle is pressed down in place. There will be a green bottom when

pressed into place, and the content of the word changes from "Press head not positioned" to "Press head has

been positioned". The display box is red if the press head is not positioned, and it is unable to perform any

mode (OPR correction, press mode, manual mode).

2) OPR status display box (button) -

It indicates whether the OPR calibration has been completed. If it has not progressed or is in progress (red

flashes), it will turn red. When the execution is completed, it will turn green and the character will change

from “OPR calibration is not completed” to “OPR calibration is completed”. This box also performs

OPR calibration. The start button will be selected after the mouse is clicked. If it is not executed, it cannot

perform any mode of continuous pressing.

Note - After performing OPR calibration and finding that the safety handle is not positioned, please select the

OPR key and then pull the safety handle after 0.5 to 1.0 seconds.

3) Manual mode -