P l e a s e G i v e P a r t N o . , D e s c r i p t i o n a n d U n i t S e r i a l N o .

HIGHWAY EQUIPMENT COMPANY

37

97372-B

Page Rev. B

LUBRICATION & MAINTENANCE CONTINUED

CONVEYOR BELT MAINTENANCE

Standard belt for the #4 conveyor has a nylon fabric that is impervious to moisture, weathering and

normal action except oil. The optional high-temperature oil resistant belting is highly recommended

when asphalt mix or impregnated fertilizers are going to be run through the spreader.

•

Inspect belt fastener occasionally for wear or "raveling" of belt grip area.

•

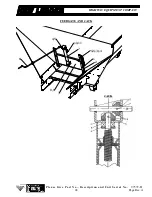

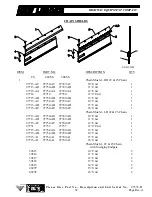

Make sure belt connecting pin is positioned correctly as shown in Figure 10.

IMPORTANT!

Pin must not rotate. If pin ends are not bent down and tight against lacing the

ends may cut into the chain shield sealers or belt wipers.

Figure 10 – Conveyor Belt Pin Installation

Hi-Temperature Belt

Achieve maximum life out of high-temperature belting by following the recommendations below:

1.

Keep the belt free from build up of asphalt or other material. Keep it clean.

2.

Spray the belt often with oil to assure flexibility of the rubber and ease cleaning. Spray the

underpart of the conveyor also, as dry heat is very harmful to the life of the belt.

3.

Keep asphalt temperature below 350

°

F and the belt running as much as possible when loaded.

A hot sitting load is more damaging since it does not allow a cooling cycle for the belt.

4.

Allow belt to flex and warm up in cold weather before loading it with extremely hot product.

5.

Do not operate the belt in temperatures below -10

°

F. Operating in temperatures below -10

°

F.

will cause the belt to crack prematurely.

A properly cared for belt, in normal use, will first experience cracking of the belt cover. This is normal

for a belt of this type in an asphalt environment and does not indicate a failing belt. Eventually the belt

cover will begin to harden and chunks of the cover begin falling off, exposing the steel. When this

happens, replace the belt.

BOTH PIN ENDS MUST

BE BENT DOWN &

TIGHT AGAINST ENDS

OF LACING

Summary of Contents for L3020G4

Page 2: ......

Page 6: ...INSERT NEW LEADER NL WARRANTY ...

Page 7: ...TAB SAFETY ...

Page 20: ...TAB OP MAINT ...

Page 111: ...TAB G4 Spread Pattern ...