63

4103241J-63/A

4103980D/A

28/05/2001

Jam clearing

2.3 Insert path

Main path of inserts in feeders D and F

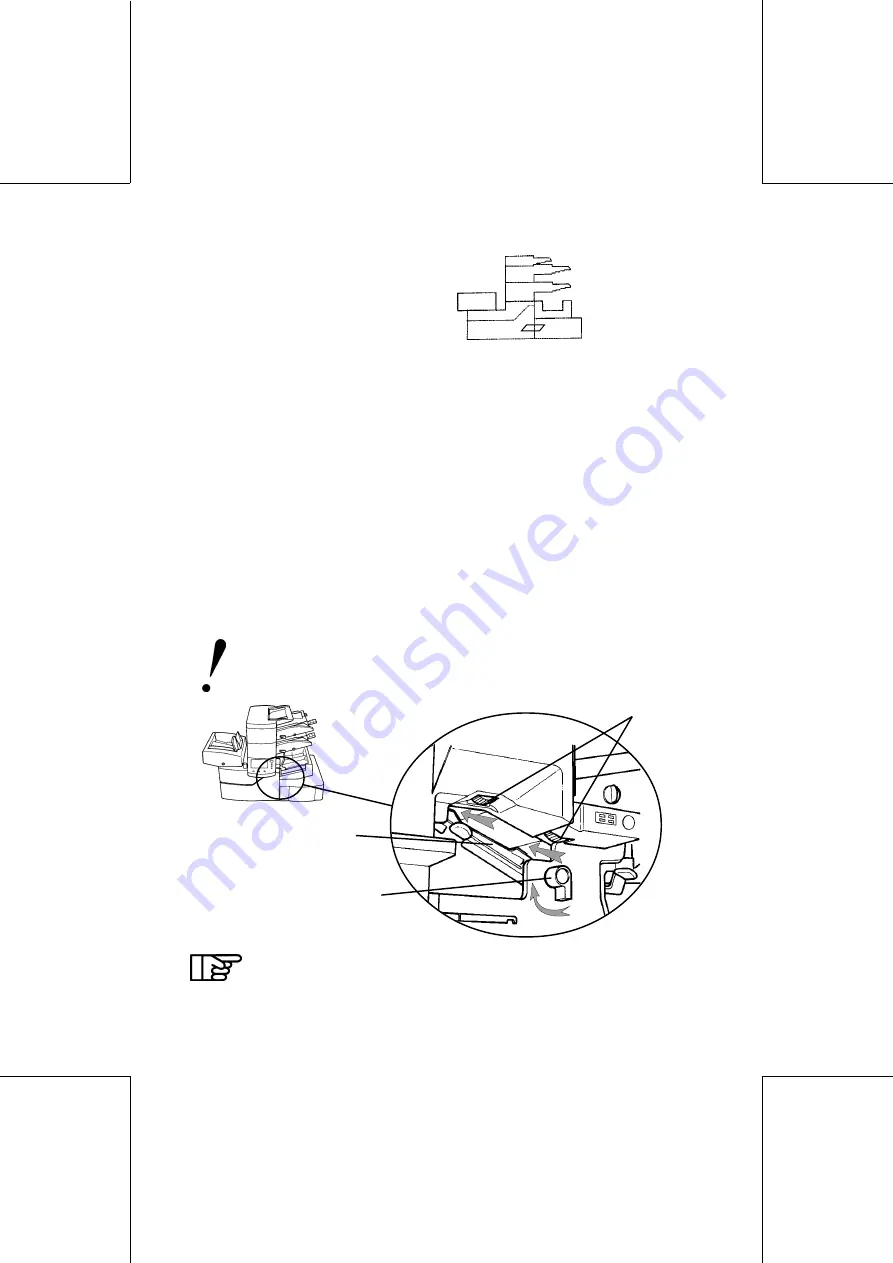

In case of a jam occurring in the main path of inserts in feeders D

and F, follow the procedure below:

- Open fully the machine and then open the right-hand and the left-

hand doors,

- Rotate the two knurled knobs

1

and

2

until the jammed insert is

visible and remove it.

- If it is not possible to move forward the insert by rotating the

knurled knobs, unlock the insert path by turning the control

3

to

the left. This will lower the platform,

- Remove the jammed insert,

- Close the machine and the two doors.

Set the machine again in its initial position (vertical)

in order to avoid any further jam.

control

3

platform

knurled knobs

1

and

2

If the insert cannot be reached, remove it from the

upper path of feeders D or F (see following

paragraphs).

Summary of Contents for SI60

Page 18: ...18 4103241J 18 A 4103980D A 28 05 2001...

Page 20: ...20 4103241J 20 A 4103980D A 28 05 2001...

Page 48: ...48 4103241J 48 A 4103980D A 28 05 2001...

Page 50: ...50 4103241J 50 A 4103980D A 28 05 2001...

Page 85: ...4103980D A 28 05 2001 SI60 FOLDER INSERTER USER S GUIDE 4103240H 01 A...

Page 87: ...4103980D A 28 05 2001 Issue 28 05 2001 4103980D A 4103240H 04 A...