qualified workshop personnel every 6 months or after 100 operating hours. If the

tool has been used without the recommended air supply, increase the inspection

intervals of the tool.Removing defects Stop using the tool as soon as you detect

any defect. Use of a defective tool may result in injury. Any repairs or

replacements to the tool components must be carried out by qualified personnel

at an authorised repair shop.

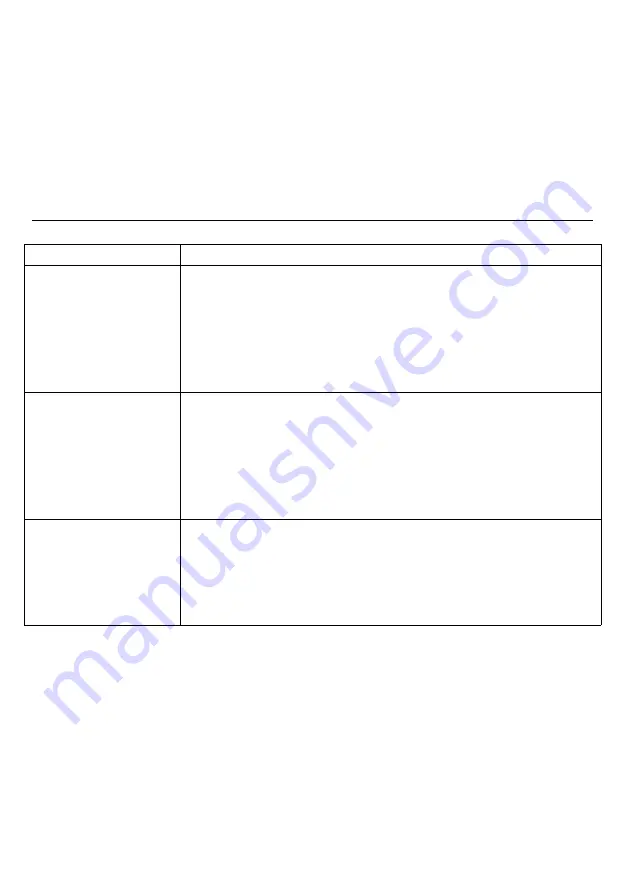

8. TROUBLESHOOTING

Problems

Possible solution

The tool rotation is

too slow or does not

start up.

Apply a small amount of WD-40 through the air inlet

opening. Activate the tool for a few seconds. The blades

could stick to the rotor. Activate the tool for approx. 30

seconds. Lubricate the tool with a small amount of oil.

Caution! Excess oil can cause the tool to lose power. In

this case, clean the drive.

The tool starts up

and then slows

down

The compressor does not provide an adequate supply of

air. The tool is activated by the air accumulated in the

compressor tank. As the tank empties, the compressor

does not keep up with filling in the air shortages. Connect

the device to a more efficient compressor.

Insufficient power

Make sure that the hoses have an internal diameter at

least . Check the pressure setting to ensure that it is set to

the maximum value. Make sure that the tool is properly

cleaned and lubricated. If there are no results, have the

tool repaired.