FX

2

ESD/EX

4 Installation

WARNING! Risk of personal injury

Always read

before install-

ation, use, service, or troubleshooting of this

product.

4.1 Delivery check

If there are any damaged or missing parts when the

product is delivered, notify the carrier and the local

Nederman representative immediately.

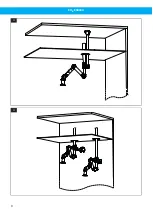

4.2 Mounting instruction

See

The extractor arm can be mounted on a wall, bench,

floor or ceiling. A mounting instruction comes togeth-

er with the accessories wall/ceiling bracket, hood and

bench bracket.

See

. The arm must always be mounted so

that the adjusting knobs on the links are on the right-

hand side.

If a UP-arrow is positioned near the duct connect-

or, the arm must only be installed so that this arrow

points upwards.

NOTE!

The extractor arm must be connected to the

earth according to

. The combina-

tion of extractor arm and extraction system

must be carried out in accordance with require-

ments of explosion prevention and protection

EN 1127-1.

See

. Make sure the arm and the duct are

properly connected.

See

. Do not use a screw with that part of the

arm.

4.2.1 Fitting the gas spring (FX

2

D100 -

L2400 only)

See

(B).

4.3 Earth control measurements after

installation

See

. Earth control measurements must only

be done by a person with appropriate competency of

explosion protected installations.

If a hood (accessory) is used the measuring should be

done from the hood. The ohmmeter must indicate less

than 106 Ω.

NOTE!

• If necessary, use a serrated washer to make

sure there is conductivity.

• Make sure the connected duct system is

grounded according to local regulations.

4.4 Damper, swivel and link adjust-

ments

The links are factory set for normal working positions.

Always check and adjust the links so they will suit the

users preference.

1

Damper open.

2

Damper closed.

5 Use

WARNING! Risk of personal injury

Always read

before install-

ation, use, service, or troubleshooting of this

product.

5.1 Arm position

. Always place the arm as close as pos-

sible to the source. When possible, place the arm side-

ways to the source for best capture, to avoid interfer-

ing with the work process, and to minimize the effect

of the cross draft. See

Always check that the airflow is sufficient in the hood

before work begins. Insufficient airflow can be due to:

• The fan impeller rotates in the wrong direction.

• Hood, arm or ducts are blocked.

For adjustments of damper, swivel and link, see

(A).

6 Maintenance

WARNING! Risk of personal injury

Always read

before install-

ation, use, service, or troubleshooting of this

product.

6.1 Routine inspection and service

Follow the list in

Chapter 10 Appendix B: Maintenance

to routinely inspect, and repair or replace

worn and damaged parts on the inside and outside of

the product.

7 Spare Parts

CAUTION! Risk of equipment damage

Use only N

$

e

$

d

$

e

$

r

$

m

$

a

$

n

$

original spare parts and ac-

cessories.

Contact your nearest authorized distributor or

N

$

e

$

d

$

e

$

r

$

m

$

a

$

n

$

for advice on technical service or

if you require help with spare parts. See also

w

$

w

$

w

$

.

$

n

$

e

$

d

$

e

$

r

$

m

$

a

$

n

$

.

$

c

$

o

$

m

$

.

7.1 Ordering spare parts

When ordering spare parts always state the following:

EN

17

Summary of Contents for FX2 Original Series

Page 8: ...FX2 ESD EX 3 4 8...

Page 9: ...FX2 ESD EX 5 6 7 9...

Page 10: ...FX2 ESD EX 8 9 10...

Page 11: ...FX2 ESD EX 106 106 106 FX Arm ESD 1 x FX Arm EX 2 x EX EX ESD EX ESD EX ESD EX EX 10 11...

Page 12: ...FX2 ESD EX 11 360 360 1 2 A B 12 12...

Page 13: ...FX2 ESD EX A 13 13...

Page 89: ...FX2 ESD EX 9 A 2 ZH 89...

Page 90: ...FX2 ESD EX ZH 10 B 2 OK 90...

Page 91: ...www nederman com...