30

Gas Furnace

DSI Control Identification Used For All Original Series Equipment

3 AMP

LOW

VOLTAGE

FUSE

MOLEX

TO HEAT

COMPONENTS

7

180

ON

ON

NEUTRALS

SPARK

TRANSFORMER

CONTROL

PLUG

FAN

OFF

DELAY

STATUS

LIGHTS

THERMOSTAT

PLUG

FUSE

Y

G

W

R

C

TEST

P3

FLAME

OK

AN2

OFF ON

SW1

AN1

1 2

F1 3 AMP

COM

SEC

IND

L1

L1

HEAT

HEAT LOW

COOL

HEAT HIGH

EAC/BLO

MODEL 1097-211

24VAC, 60Hz., .5A MAX.

ANSI Z21.20 AUTOMATIC

1097-83-211B HSCI

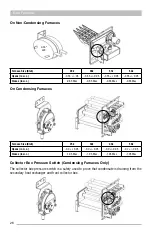

TIME

90

120

160

180

SWITCH 1

OFF

OFF

ON

ON

SWITCH 2

ON

OFF

OFF

ON

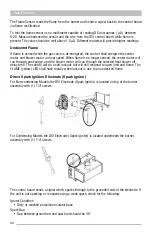

Combustion

Air Proving Switch

The

combustion

air

proving

switch

is

a

pressure

sensitive

switch

that

monitors

air

pressure

to

ensure

that

proper

combustion

air

flow

is

available.

The

switch

is

a

single

pole/normally

open

device that

closes

when a

decreasing pressure is

sensed in the

venter

housing.

On

start-up

when

the

heater

is

cold,

the

sensing

pressure

is

at

the

most

negative

level,

and

as

the

heater

warms

up,

the

sensing

pressure

becomes

less

negative.

After

the

system

has

reached

equilibrium

(about

10

minutes),

the

sensing

pressure

levels

off.

All

units

are

equipped

with

a

temperature

activated

manually

reset

switch.

The

flame

rollout

switch

is

located

centrally

on

the

top

of

the

burner

assembly.

It

is

factory

set

and

is

non-ad-

justable.

If

the

setpoint

is

reached,

the

flame

rollout

acts

to

interrupt the electric supply to the gas valve. If

the flame rollout

switch

activates,

identify

and

correct

the

cause

before

resetting

the

switch.

Refer

to

the

Maintenance

Section

for

information

on

probable

causes

and

instructions

on

resetting

the

flame

rollout

switch.

The

hea

ter

ha

sa

one-pie

ce

burner

designed

to

provid

e

controlled

flame

stability

without

lifting

or

flashback

with

either

natural

or

propane

gas.

The

burner

can

be

removed

as

a

unit

for

inspection

or

service.

The

main

operating

gas

valve

is

powered

by

the

24-volt

control

circuit

through

the

thermostat

and

safety

controls.

The

main

control

valve

is

of

the

diaphragm

type

providing

regulated

gas

flow

preset

at

the

factory.

W

ARNING:

THE

OPERA

TING

VAL

VE

IS

THE

PRIME

SAFETY

SHUT

OFF

.

ALL

GAS

SUPPL

Y

LINES

MUST

BE

FREE

OF

DIRT

OR

SCALE

BEFORE

CONNECTING

THE

UNIT

TO

ENSURE

POSITIVE

CLOSURE.

SEE

HAZARD

INTENSITY

LEVELS,

PAGE

2.

Burner

Gas V

alve

EXTENDED

FAN TIME

DIP SWITCH

SETTING

INPUT

FAN OUTPUT-

COOLING

FAN OUTPUT-

HEATING

INDUCER FAN

OUTPUT

SPARK

IGNITOR

OUTPUT

LOW

VOLTAGE

COMMON

24V

LOW

VOLTAGE

SECONDARY

24V

GREEN – CONTROL

INDICATOR LIGHT

(FAULT CODES)

YELLOW – FLAME

INDICATOR LIGHT

(FLAME ONLY)

MOLEX CONNECTION

TO T-STAT WIRE

(Y-G-W-R-C)

Summary of Contents for CPG41838-U

Page 2: ...2...

Page 5: ...5 Unit Dimensions Original R22 with Gas Heat A B Series 43...

Page 6: ...6 Original R22 with Electric Heat A B Series Unit Dimensions...

Page 7: ...7 Unit Dimensions Original R410A with Gas Heat B C D E Series...

Page 8: ...8 Unit Dimensions Original R410A with Electric Heat B C D E Series...

Page 9: ...9 Unit Dimensions U Series R410A 80 Gas Heat...

Page 10: ...10 Unit Dimensions U Series R410A up to 95 Gas Heat...

Page 11: ...11 Unit Dimensions U Series R410A Electric Heat...

Page 19: ...19 Gas Furnace 3 Remove the 11 screws 4 Remove the front furnace baffle...

Page 46: ...46 Chassis Cooling Section...

Page 79: ...79...