Summary of Contents for CPG41838-U

Page 2: ...2...

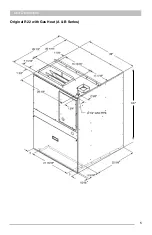

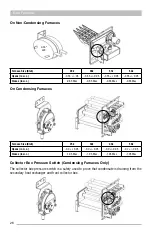

Page 5: ...5 Unit Dimensions Original R22 with Gas Heat A B Series 43...

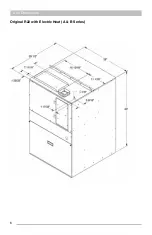

Page 6: ...6 Original R22 with Electric Heat A B Series Unit Dimensions...

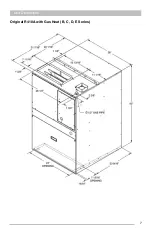

Page 7: ...7 Unit Dimensions Original R410A with Gas Heat B C D E Series...

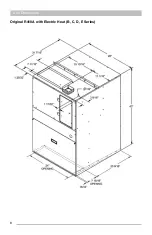

Page 8: ...8 Unit Dimensions Original R410A with Electric Heat B C D E Series...

Page 9: ...9 Unit Dimensions U Series R410A 80 Gas Heat...

Page 10: ...10 Unit Dimensions U Series R410A up to 95 Gas Heat...

Page 11: ...11 Unit Dimensions U Series R410A Electric Heat...

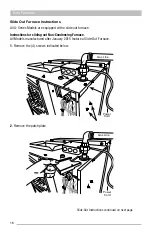

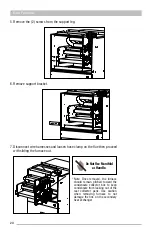

Page 19: ...19 Gas Furnace 3 Remove the 11 screws 4 Remove the front furnace baffle...

Page 46: ...46 Chassis Cooling Section...

Page 79: ...79...