15

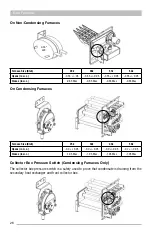

Heat Module P/N

14208384

14208385

14208386

14208387

Input (BTU) (NG)

25,000

32,000

43,000

50,000

Output (BTU) (NG)

23,750

30,400

40,850

47,500

Input (BTU) (LP)

25,000

N/A

35,000

50,000

Output (BTU) (LP)

23,750

N/A

33,250

47,500

Max External Static Pressure (in w.c.)

0.4

0.4

0.4

0.4

Temperature Rise (°F)

30 to 60

35 to 65

35 to 65

40 to 70

Blower Speed Setting

Med. Low (4)

Med. Low (4)

Med. High (2)

High (1)

Orifice Size (NG)

51

48

50

47

Orifice Size (LP)

58

N/A

60

56

Nominal Temperature Rise (°F)

45

50

50

55

Allowable Air Temperature Range (°F)

130-160

135-165

135-165

140-170

CO

2

%- Acceptable Range

6 TO 7

6 TO 7

6 TO 7

6 TO 7

CO

1

- Air Free - ppm

0-200

0-200

0-200

0-200

Sensing Cold (in w.c.)

1.3 +/- .1

1.05 +/- .1

1.05 +/- .1

1.05 +/- .1

Stack Temperature (°F)

80-140

80-140

80-140

80-140

4. Heat Blower On Delay

– The control waits for 20 seconds from the time the gas valve

opened and then energizes the blower motor. The gas valve and venter motor remain

energized. The control proceeds to 5. Steady Heat.

5. Steady Heat

– The control continuously monitors the safeties (high limit, roll-out, and

pressure) for open switches, the flame sensor for proving, and the thermostat for a call for

heat. When the thermostat's call for heat is removed, the control de-energizes the gas valve

and begins (6.) Post-purge and (7.) Blower Off Delay.

6. Post-purge

– The venter motor output remains on for a 30-second post-purge period after

the thermostat is satisfied.

7. Blower Off Delay

– The blower motor is de-energized after a 90 second blower off delay

(field adjustable, see pages 29-31). Timing begins when the thermostat is satisfied.

Abnormal Functions

• Interrupted Thermostat Call for Heat

– If the thermostat demand for heat is removed before

the flame is recognized, the control will run the venter motor for the post purge period and

de-energize all outputs. If the thermostat demand for heat is removed after successful ignition,

the control will de-energize the gas valve, run the venter motor through post purge, and run the

blower motor on heat speed for the selected delay off time.

• Soft Lockout

– The control shall not initiate a call for heat or call a for continuous fan while

in lockout. The control will still respond to an open limit and undesired flame. Lockout shall

automatically reset after one hour. Lockout may be manually reset by removing power from the

control for more than one second or removing the thermostat call for heat for at least 1 second

but no more than 20.

• Hard Lockout

– If the control detects a fault on the control board, the status LED will be

de-energized, and the control will lockout for as long as the fault remains. A hard lockout will

automatically reset if the hardware fault clears.

• Power Interruption

– During a momentary power interruption or at voltage levels below the

minimum operating voltage for line voltage the system will self-recover without lockout when

voltage returns to the operating range. During a momentary power interruption of the 24V

control voltage, the board will enter a soft lockout. (Power interruptions of less than 80ms shall

not cause the control to change operating states. Power interruptions greater than 80ms may

cause the control to interrupt the current operating cycle and restart.)

• Ignition Retry

– If a flame is not established on the first trial for ignition, the control

de-energizes the gas valve and the venter motor remains energized for an inter-purge period of

30 seconds. The spark and gas valve are then re-energized and the control initiates another trial

for ignition. If a flame is not established on the second trial, the control de-energizes the gas

valve, energizes the blower motor on heat speed, and the venter motor remains energized. The

blower motor is shut off after a short period. When the blower motor de-energizes, the spark

and gas valve are re-energized, and the control initiates another trial for ignition. (This blower

delay is a self-healing feature for an open auxiliary limit switch). If a flame is not established on

the third trial for ignition, the control de-energizes the gas valve, and the venter motor remains

energized for an inter-purge period of 30 seconds. The control then re-energizes the spark

and gas valve and initiates another trial for ignition. If a flame is not established on the fourth

trial for ignition (initial try plus 3 re-tries), the control de-energizes the gas valve and goes

into lockout. The control displays a one flash code on the green LED to indicate ignition failure

lockout.

Gas Furnace

Summary of Contents for CPG41838-U

Page 2: ...2...

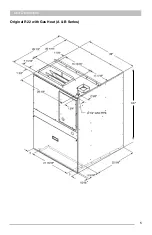

Page 5: ...5 Unit Dimensions Original R22 with Gas Heat A B Series 43...

Page 6: ...6 Original R22 with Electric Heat A B Series Unit Dimensions...

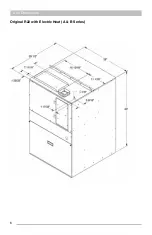

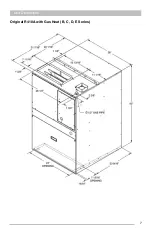

Page 7: ...7 Unit Dimensions Original R410A with Gas Heat B C D E Series...

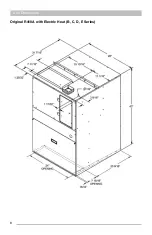

Page 8: ...8 Unit Dimensions Original R410A with Electric Heat B C D E Series...

Page 9: ...9 Unit Dimensions U Series R410A 80 Gas Heat...

Page 10: ...10 Unit Dimensions U Series R410A up to 95 Gas Heat...

Page 11: ...11 Unit Dimensions U Series R410A Electric Heat...

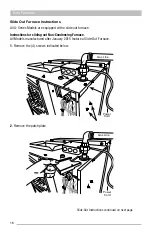

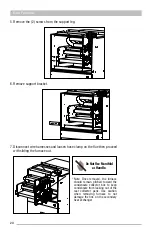

Page 19: ...19 Gas Furnace 3 Remove the 11 screws 4 Remove the front furnace baffle...

Page 46: ...46 Chassis Cooling Section...

Page 79: ...79...