17

W415-0341 / F / 11.21.05

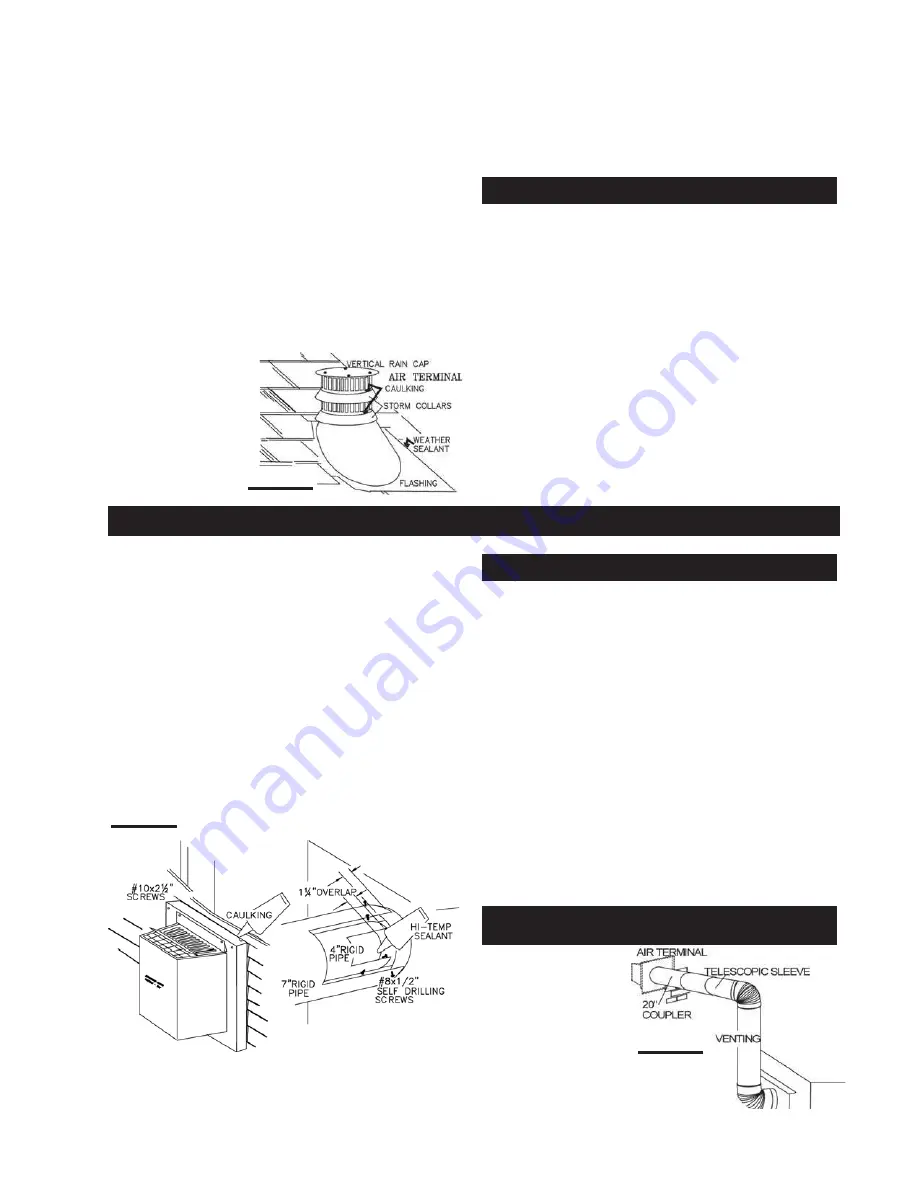

1.

Move the fireplace into position. Measure the vent length

required between terminal and fireplace taking into ac-

count the additional length needed for the finished wall

surface and any 1¼" overlaps between venting compo-

nents.

2.

Apply high temperature sealant to the outer edge of

the 4" inner collar of the fireplace. Attach the first vent com-

ponent and secure using 3 self tapping screws. Repeat

using 7" piping.

3.

Holding the air terminal (lettering in an upright, read-

able position), insert into both vent pipes with a twisting

motion to ensure that both the terminal sleeves engage

into the vent pipes and the sealant. Secure the terminal to

the exterior wall and make weather tight by sealing with

caulking (not supplied).

The air terminal mounting plate may be recessed into

the exterior wall or siding by 1½", the depth of the return

flange.

A 45° corner installation

can have 0 inch rise

between the fireplace

combustion air collar

and the air terminal.

In

this case, vent lengths

must be kept to a maxi-

mum of 24". For longer

vent lengths, a mini-

mum vertical rise of 24"

is required.

FIGURE 32

EXTENDED HORIZONTAL AND CORNER

AIR TERMINAL INSTALLATION

For safe and proper operation of the fire-

place, follow the venting instructions exactly.

For optimum performance, it is recommended that hori-

zontal runs have a minimum ¼ inch rise per foot when

using Wolf Steel or Simpson Duravent rigid vent com-

ponents.

The vent system must be supported approximately every 3

feet for both vertical and horizontal runs. Use Wolf Steel

vent spacers

W615-0033

every 3 feet on either side of each

elbow to maintain the minimum 1¼" clearance between

the outer and inner vent pipes. Use Napoleon support ring

assembly

W010-0370

or equivalent noncombustible strap-

ping to maintain the minimum clearance to combustibles

for both vertical and horizontal runs.

FIGURE 31

5.

Remove nails from the shingles, above and to the

sides of the chimney. Place the flashing over the air termi-

nal and slide it underneath the sides and upper edge of the

shingles. Ensure that the air terminal is properly centred

within the flashing, giving a 3/4" margin all around. Fasten

to the roof. Do

not

nail through the lower portion of the

flashing. Make weather-tight by sealing with caulking. Where

possible, cover the sides and top edges of the flashing

with roofing material.

6.

Apply a heavy bead of weatherproof caulking 2 inches

above the flashing. Slide the storm collar around the air

terminal and down to the caulking. Tighten to ensure that a

weather-tight seal between the air terminal and the collar

is achieved. Attach the other storm collar centred between

the air intake and the air exhaust slots onto the air terminal.

Tighten securely. Attach the vertical rain cap.

Spacers are attached

to the 4" inner flex

liner at predetermined

intervals to maintain

a 1-1/4" air gap to the

7" outer liner. These

spacers must not be

removed.

7.

If more liner needs to be used to reach the fireplace,

couple them together as illustrated. The vent system must be

supported approximately every 3 feet for both vertical and

horizontal runs. Use noncombustible strapping to maintain a

clearance to combustibles of 1".

1.

Install the 4 inch diameter aluminium flexible liner to

the fireplace. Secure with 3 screws and flat washers. Seal

the joint and screw holes using the high temperature seal-

ant provided.

2.

Install the 7 inch diameter aluminium flexible liner to

the fireplace. Attach and seal the joints.

FIREPLACE VENT CONNECTION

USING RIGID VENT COMPONENTS

HORIZONTAL AIR TERMINAL INSTALLATION

FIGURE 30