S-67

03-M Series, WSM

DIESEL ENGINE

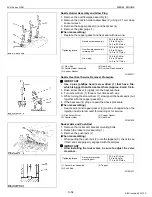

Crankshaft

NOTE

Q

• Before disassembling, check the side clearance of

crankshaft. Also check it during reassembling.

For D1503-M, D1703-M and V2203-M

1. Remove the main bearing case screw 2 (1).

2. Pull out the crankshaft assembly, taking care not to damage the

crankshaft bearing 1 (3).

For D1803-M

1. Remove the main bearing case screw 2 (1).

2. Turn the crankshaft to set the crank pin of the third cylinder to the

bottom dead center. Then draw out the crankshaft until the crank

pin of the second cylinder comes to the center of the third

cylinder.

3. Turn the crankshaft by 2.09 rad (120

°

) counterclockwise to set

the crank pin of the second cylinder to the bottom dead center.

Draw out the crankshaft until the crank pin of the first cylinder

comes to the center of the third cylinder

4. Repeat the above steps to draw out all the crankshaft.

For V2403-M

1. Remove the main bearing case screw 2 (1).

2. Turn the crankshaft to set the crank pin of the 4th cylinder to the

horizontal directions (Right or Left). Then draw out all the

crankshaft, holding the crank pins to the horizontal directions

(Right or Left).

(When reassembling)

IMPORTANT

Q

• Install the crankshaft sub assembly, aligning the screw hole

of main bearing case 2 (2) with the screw hole of cylinder

block.

• When tightening the main bearing case screw 2 (1), apply oil

to the screw and screw by hand before tightening the

specific torque.

If not smooth to screw by hand, align the screw holes

between the cylinder block and the main bearing case.

W1066311

Tightening torque

Main bearing case screw 2

68.6 to 73.5 N·m

7.0 to 7.5 kgf·m

50.6 to 54.2 ft-lbs

(1) Main Bearing Case Screw 2

(2) Main Bearing Case 2

(3) Crankshaft bearing 1

(a) Cut place for removing and

installing the crankshaft

[A] D1803-M

KiSC issued 08, 2012 A