15

WWW

.N

AKAYAMA

T

OOLS

.

COM

Minimize Wear and Avoid Damage

Observing the instructions in this manual helps reduce the risk of unnecessary wear and damage to the power tool.

The power tool must be operated, maintained and stored with the due care and attention described in this owner's manual.

The user is responsible for all damage caused by non-observance of the safety precautions, operating and maintenance

instructions in this manual. This includes in particular:

- Alterations or modifications to the product not approved by dealer.

- Using attachments, Power Tool Attachments or cutting tools not approved by dealer.

- Using the product for purposes for which it was not designed.

- Using the product for sports or competitive events.

- Consequential damage caused by continuing to use the product with defective components.

Maintenance Work

All the operations described in the "Maintenance Chart" must be performed on a regular basis. If these maintenance

operations cannot be performed by the owner, they should be performed by an authorized servicing dealer.

If these operations are not carried out as specified, the user assumes responsibility for any damage that may occur. Among

other things, this includes:

- Damage to the engine due to neglect or deficient maintenance (e.g. of air and fuel filters), incorrect carburettor adjustment

or inadequate cleaning of cooling air inlets (intake ports, cylinder fins).

- Corrosion and other consequential damage resulting from improper storage.

- Damage and consequential damage resulting from the use of parts other than original replacement parts.

- Damage resulting from maintenance or repair work performed by authorized servicing dealers.

Parts Subject to Wear and Tear

Some parts of the power tool are subject to normal wear and tear even during regular operation in accordance with

instructions and, depending on the type and duration of use, have to be replaced in good time.

Among other parts, this includes:

- Filters (air, fuel)

- Fan wheel

- Starter mechanism

- Spark plug

- Components of anti-vibration system

Summary of Contents for BL4300

Page 1: ...BL4300 Owner s manual Art Nr 023456 WWW NAKAYAMATOOLS COM...

Page 2: ...2 WWW NAKAYAMATOOLS COM GR 1 2...

Page 3: ...3 WWW NAKAYAMATOOLS COM...

Page 4: ...4 WWW NAKAYAMATOOLS COM OFF 3 10...

Page 5: ...5 WWW NAKAYAMATOOLS COM Service OFF ON...

Page 6: ...6 WWW NAKAYAMATOOLS COM 90 Premium...

Page 7: ...7 WWW NAKAYAMATOOLS COM TC H 1 2 TC 25 1...

Page 8: ...8 WWW NAKAYAMATOOLS COM 1 ON 2...

Page 9: ...9 WWW NAKAYAMATOOLS COM 2 1 OFF OFF ON 5 15...

Page 10: ...10 WWW NAKAYAMATOOLS COM 1 2 H L 1 4 H L LA L LA...

Page 11: ...11 WWW NAKAYAMATOOLS COM LA L H H 1 4 A 100 1 2 3 Service...

Page 12: ...12 WWW NAKAYAMATOOLS COM 1 2 3 4 5 6 7 5 4 3...

Page 13: ...13 WWW NAKAYAMATOOLS COM OFF 3 UV 43cc 1 7hp 12m3 min 4200m3 min 1 2L Service...

Page 14: ...14 WWW NAKAYAMATOOLS COM 12 x x x x x x x x x x x x x x x x x x x x x Service x...

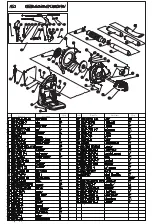

Page 15: ...15 WWW NAKAYAMATOOLS COM Service...

Page 30: ...Ser No Part No Part Name Qty Ser No Part No Part Name Qty...

Page 31: ...Ser No Part No Part Name Qty Ser No Part No Part Name Qty...