12

WWW

.N

AKAYAMA

T

OOLS

.

COM

•

Remove the spring clip

(3)

.

•

Remove the rope rotor with washer

(4)

and pawl

(5)

. Ease the cap (6) out

of the starter grip.

•

Remove remaining rope from the rotor and grip.

•

Tie a simple overhand knot in the end of the new starter rope (see Specifications) and then thread the rope through

the top of the grip and the rope bush

(7)

.

•

Refit the cap in the grip.

•

Thread the rope through the rotor and secure it in the rotor with a simple overhand knot.

•

Fit the pawl (5) in the rotor and slip the washer (4) over the starter post.

•

Use a screwdriver or suitable pliers to install the spring clip (3) on starter post and over the peg on the pawl-the spring clip

must point clock wise - see illustration. Go to "Tensioning rewind spring".

Replacing a broken rewind spring

•

Lubricate the new spring with a few drops of non-resinous oil. Remove the rope rotor as described in "Replacing the starter

rope". Remove parts of old spring.

•

Fit new spring housing - bottom plate must face downward. Engage outer spring loop over the lug. Refit the rope rotor.

Go to "Tensioning rewind spring".

If the spring pops out and uncoils during installation: Refit it in the spring housing in the counter- clockwise direction - start

outside and work inward.

Summary of Contents for BL4300

Page 1: ...BL4300 Owner s manual Art Nr 023456 WWW NAKAYAMATOOLS COM...

Page 2: ...2 WWW NAKAYAMATOOLS COM GR 1 2...

Page 3: ...3 WWW NAKAYAMATOOLS COM...

Page 4: ...4 WWW NAKAYAMATOOLS COM OFF 3 10...

Page 5: ...5 WWW NAKAYAMATOOLS COM Service OFF ON...

Page 6: ...6 WWW NAKAYAMATOOLS COM 90 Premium...

Page 7: ...7 WWW NAKAYAMATOOLS COM TC H 1 2 TC 25 1...

Page 8: ...8 WWW NAKAYAMATOOLS COM 1 ON 2...

Page 9: ...9 WWW NAKAYAMATOOLS COM 2 1 OFF OFF ON 5 15...

Page 10: ...10 WWW NAKAYAMATOOLS COM 1 2 H L 1 4 H L LA L LA...

Page 11: ...11 WWW NAKAYAMATOOLS COM LA L H H 1 4 A 100 1 2 3 Service...

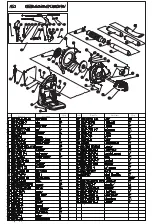

Page 12: ...12 WWW NAKAYAMATOOLS COM 1 2 3 4 5 6 7 5 4 3...

Page 13: ...13 WWW NAKAYAMATOOLS COM OFF 3 UV 43cc 1 7hp 12m3 min 4200m3 min 1 2L Service...

Page 14: ...14 WWW NAKAYAMATOOLS COM 12 x x x x x x x x x x x x x x x x x x x x x Service x...

Page 15: ...15 WWW NAKAYAMATOOLS COM Service...

Page 30: ...Ser No Part No Part Name Qty Ser No Part No Part Name Qty...

Page 31: ...Ser No Part No Part Name Qty Ser No Part No Part Name Qty...