10

WWW

.N

AKAYAMA

T

OOLS

.

COM

Dirty air filers reduce engine power increase fuel consumption and make starting more difficult.

If there is a noticeable loss of engine power

•

Turn choke knob to

•

Release the screws (1) and pull off the filter cover (2).

•

Remove the filter from the cover and inspect it - if it is dirty or damaged, clean the filter or fit a new one.

•

Install the main filter and pre-filter elements in the filter cover.

•

Fit the cover on the filter base and tighten it down firmly.

Carburetor

General information

Your carburetor comes from the factory with a standard setting.

This setting provides an optimum fuel-air mixture under most operating conditions.

The high speed screw alters the engine's power output and the maximum off-load engine speed.

If the setting is too lean there is a risk of engine damage due to insufficient lubrication and overheating.

Standard Setting

Carburetor with limiter caps

•

Shut off the engine.

•

Screw down the high speed screw (H) and low speed screw (L) counterclockwise as far as

stop (no more than 1/4 turn).

Carburetor without limiter caps

•

Shut off the engine.

•

Carefully screw both adjusting screws down onto their seats (clockwise).

•

Open the high speed screw (H) one full turn.

•

Open the low speed screw (L) one full turn.

Adjusting idle Speed

Engine stops while idling

•

Carry out standard setting on low speed screw.

•

Turn the idle speed screw (LA) clockwise until the engine runs smoothly.

Erratic idling behavior, poor acceleration

•

Carry out standard setting on low speed screw.

•

Turn low speed screw (L) counterclockwise until the engine runs and accelerates

smoothly.

It is usually necessary to change the setting of the idle speed screw (LA) after every

correction to the low speed screw (L).

Fine Tuning for Operation at High Altitude

A slight correction of the setting may be necessary if engine power is not satisfactory when operating at high altitude:

•

Check the standard setting.

•

Warm up the engine.

•

Turn the high speed screw

(H)

slightly clockwise (leaner). On models with limiter caps, turn high speed screw

(H)

1/4 turn,

but no further than stop.

If the

setting is too lean

there is a

risk of engine damage

due to insufficient lubrication and overheating.

Checking the Spark Plug

If engine is down on power, difficult to start or runs poorly at idle speed first check the spark

plug.

•

Remove the spark plug - see "Starting / Stopping the Engine"

•

Check electrode gap (A) and readjust if necessary - see "Specifications".

LA

Summary of Contents for BL4300

Page 1: ...BL4300 Owner s manual Art Nr 023456 WWW NAKAYAMATOOLS COM...

Page 2: ...2 WWW NAKAYAMATOOLS COM GR 1 2...

Page 3: ...3 WWW NAKAYAMATOOLS COM...

Page 4: ...4 WWW NAKAYAMATOOLS COM OFF 3 10...

Page 5: ...5 WWW NAKAYAMATOOLS COM Service OFF ON...

Page 6: ...6 WWW NAKAYAMATOOLS COM 90 Premium...

Page 7: ...7 WWW NAKAYAMATOOLS COM TC H 1 2 TC 25 1...

Page 8: ...8 WWW NAKAYAMATOOLS COM 1 ON 2...

Page 9: ...9 WWW NAKAYAMATOOLS COM 2 1 OFF OFF ON 5 15...

Page 10: ...10 WWW NAKAYAMATOOLS COM 1 2 H L 1 4 H L LA L LA...

Page 11: ...11 WWW NAKAYAMATOOLS COM LA L H H 1 4 A 100 1 2 3 Service...

Page 12: ...12 WWW NAKAYAMATOOLS COM 1 2 3 4 5 6 7 5 4 3...

Page 13: ...13 WWW NAKAYAMATOOLS COM OFF 3 UV 43cc 1 7hp 12m3 min 4200m3 min 1 2L Service...

Page 14: ...14 WWW NAKAYAMATOOLS COM 12 x x x x x x x x x x x x x x x x x x x x x Service x...

Page 15: ...15 WWW NAKAYAMATOOLS COM Service...

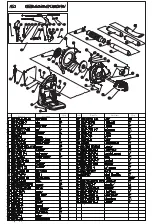

Page 30: ...Ser No Part No Part Name Qty Ser No Part No Part Name Qty...

Page 31: ...Ser No Part No Part Name Qty Ser No Part No Part Name Qty...