Nailor Industries Inc. reserves the right to change any information concerning product or pricing without notice.

SCHEDULE TYPE:

PROJECT:

ENGINEER:

CONTRACTOR:

DATE

B SERIES

SUPERSEDES DRAWING NO.

4 - 5 - 18

3000

NEW

D3001Q-2

Page 1 of 1.

Dimensions are in inches (mm).

SINGLE DUCT TERMINAL UNIT WITH

DISSIPATIVE SILENCER • SUPER QUIET

DIGITAL CONTROLS • VARIABLE OR CONSTANT VOLUME

MODEL: D3001Q WITH BOTTOM MOUNT CONTROLS

LOCATION (OPTION OB)

Standard Features:

Options and Accessories:

q

24 VAC control transformer.

q

Side access door.

q

Controls enclosure for field mounted

controls.

q

Dust tight enclosure seal.

q

FMI Removable insert type Diamond

Flow Sensor.

q

Hanger brackets.

q

Toggle disconnect switch.

q

Special Features: ______________ .

Terminal Unit Liner:

q

Fiber-free liner.

q

Perforated metal liner.

q

Solid metal liner.

q

Steri-liner.

q

Steri-liner + Perforated metal liner.

Silencer Acoustic Media:

q

Fiberglass Cloth liner.

q

Mylar/Spacer liner.

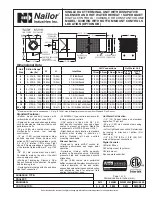

H

SLIP AND DRIVE

CONNECTION

51 1/2" (1308)

36" (914)

OPTIONAL (FMI)

REMOVABLE

FLOW SENSOR

OPTIONAL SIDE

ACCESS DOOR

RECTANGULAR

DISSIPATIVE

SILENCER

14" (356)

5 1/2"

(140)

6"

(152)

1/2"

(13)

INLET: ROUND,

FLAT OVAL OR

RECTANGULAR

MULTI-POINT

AVERAGING

FLOW SENSOR

11" (279)

1/2"

(13)

W

H

DAMPER

DRIVESHAFT

CONTROLS ENCLOSURE

FOR FACTORY

MOUNTED CONTROLS

AIRFLOW

W

*

Maximum airflow limit is based upon 1.5" w.g. (373 Pa) max. differential pressure signal from Diamond Flow Sensor.

Unit

Size

Airflow Range*

cfm (I/s)

W

H

Inlet Size

4

0 – 225 (0 – 106)

10 (254)

10 (254)

3 7/8 (98) Round

5

0 – 400 (0 – 189)

10 (254)

10 (254)

4 7/8 (124) Round

6

0 – 550 (0 – 260)

10 (254)

10 (254)

5 7/8 (149) Round

7

0 – 800 (0 – 378)

12 (305)

12 1/2 (318)

6 7/8 (175) Round

8

0 – 1100 (0 – 519)

12 (305)

12 1/2 (318)

7 7/8 (200) Round

9

0 – 1400 (0 – 661)

14 (356)

12 1/2 (318)

8 7/8 (225) Round

10

0 – 1840 (0 – 868)

14 (356)

12 1/2 (318)

9 7/8 (251) Round

12

0 – 2500 (0 – 1180)

18 (457)

12 1/2 (318)

12 15/16 x 9 13/16 (329 x 249) Oval

14

0 – 3125 (0 – 1475)

24 (610)

12 1/2 (318)

16 1/16 x 9 13/16 (408 x 249) Oval

16

0 – 3725 (0 – 1758)

28 (711)

12 1/2 (318)

19 3/16 x 9 13/16 (487 x 249) Oval

24 x 16

0 – 8330 (0 – 3931)

38 (965)

18 (457)

23 7/8 x 15 7/8 (606 x 403) Rect.

Dimensional Data

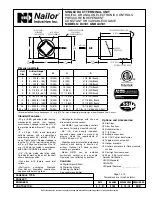

• Bottom mount controls location with

vertical drive shaft (option code OB).

• Designed for noise sensitive applications

such as classrooms, libraries, studios and

performance halls.

• 22 ga. (0.86) zinc coated steel casing,

mechanically sealed, low leakage

construction.

• 16 ga. (1.63) corrosion-resistant steel

inclined opposed blade damper with

extruded PVC seals (single blade on size

4, 5, 6). 45

°

rotation, CW to close. Tight

close-off. Damper leakage is less than 2%

of the terminal rated airflow at 3" w.g. (750 Pa).

• 1/2" (13) dia. plated steel drive shaft.

An indicator mark on the end of the shaft

shows damper position.

•

Multi-point averaging Diamond Flow

Sensor. Aluminum construction. Supplied

with balancing tees.

• Rectangular discharge with slip and drive

cleat duct connection.

• Full NEMA 1 type controls enclosure for

factory mounted controls.

• VAV section is lined with 3/4" (19),

dual density insulation, exposed edges

coated to prevent air erosion. Meets the

requirements of NFPA 90A and UL 181.

• Right-hand controls location is standard

(shown) when looking in direction of airflow.

Optional left hand controls mounting is

available.

Silencer Section:

• Designed to mate w/VAV section for

optimum performance and super quiet

operation.

•

Optimized internal baffle geometry

reduces self-generated noise, minimizes

pressure drop and maximizes acoustic

attenuation.

• 22 ga. (0.86) coated steel perforated

baffles encapsulate fiberglass acoustic media.

• Internal insulation on top and bottom

exposed panels optimizes sound reduction

and eliminates need for external field

applied thermal duct wrap.