Nailor Industries Inc. reserves the right to change any information concerning product or pricing without notice.

SCHEDULE TYPE:

PROJECT:

ENGINEER:

CONTRACTOR:

Page 1 of 1.

Dimensions are in inches (mm)

DATE

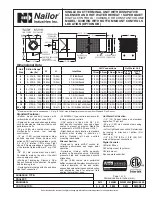

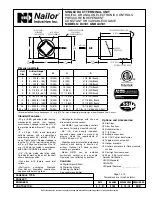

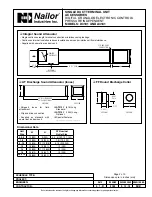

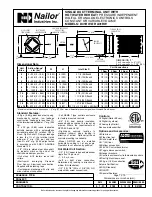

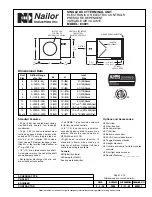

B SERIES

SUPERSEDES DRAWING NO.

3 - 18 - 18

3000

10 - 28 - 16

D30HQW

SINGLE DUCT TERMINAL UNIT WITH HOT WATER

REHEAT AND DISSIPATIVE SILENCER

HOSPITAL GRADE • SUPER QUIET

DIGITAL CONTROLS • VARIABLE OR CONSTANT VOLUME

MODEL: D30HQW

5 1/2"

(140)

OPTIONAL

ACCESS DOOR

H

H

DAMPER

DRIVESHAFT

L

W

H

W

6"

(152)

1/2"

(13)

11"

(279)

H

15 1/2" (394)

63 1/2" (1613)

14" (356)

48" (1219)

AIRFLOW

OPTIONAL

FMI

REMOVABLE

FLOW SENSOR

CONTROLS ENCLOSURE

FOR FACTORY MOUNTED

CONTROLS

MULTI-POINT

AVERAGING

FLOW SENSOR

6"

(152)

RECTANGULAR DISSIPATIVE

MYLAR LINED SILENCER

SLIP AND DRIVE

CONNECTION

INLET: ROUND,

FLAT OVAL OR

RECTANGULAR

Dimensional Data

Standard Features:

• Designed for hospital and other critical

environment applications where IAQ is a

concern.

• 22 ga. (0.86) zinc coated steel casing,

mechanically sealed, low leakage

construction.

• 16 ga. (1.63) corrosion-resistant steel

inclined opposed blade damper with

extruded PVC seals (single blade on size

4, 5, 6). 45

O

rotation, CW to close. Tight

close-off. Damper leakage is less than 2%

of the terminal rated airflow at 3" w.g. (750 Pa).

•1/2" (13) dia. plated steel drive shaft.

An indicator mark on the end of the shaft

shows damper position.

• Multi-point averaging Diamond Flow

Sensor. Aluminum construction. Supplied

with balancing tees.

• Rectangular discharge with slip and

drive cleat duct connection.

• Full NEMA 1 type controls enclosure for

factory mounted controls.

• VAV section is lined with 13/16" (21),

thick, 4 lb. density Steri-Liner insulation.

Fiberglass with a reinforced aluminum

FSK facing. Meets the requirements of

NFPA 90A, UL 181 and ASTM C655.

"Notch and tuck" fabrication and full seam

length steel Z-strip construction.

• Right-hand controls location is standard

(shown) when looking in direction of

airflow. Optional left hand controls

mounting is available.

Silencer Section:

• Designed to mate with VAV section for

optimum performance and super quiet

operation.

•

Optimized internal baffle geometry

reduces self-generated noise, minimizes

pressure drop and maximizes acoustic

attenuation.

• 22 ga. (0.86) coated steel perforated

baffles encapsulate fiberglass acoustic

media. Mylar lining with acoustical spacer

isolates material from airstream.

• Internal Steri-Liner insulation on top and

bottom optimizes sound reduction and

eliminates need for external field applied

thermal duct wrap.

Hot Water Coil Section:

• 1/2" (13) Copper tubes and aluminum

ripple fins, 10 per inch.

• 20 ga. (1.00) zinc coated steel casing

Uninsulated.

• Left or right hand connection. Determined

by looking in direction of airflow (RH

illustrated).

• 1/2" (13), 7/8" (22) or 1 3/8" (35) O.D.

male solder sweat connections.

Digital Controls:

q

Nailor EZvav.

q

Factory mount (by others).

q

Field mount.

See separate submittal.

Options and Accessories:

q

Bottom access door.

q

FMI Removable insert type Diamond

Flow Sensor.

q

24 VAC control transformer.

q

Toggle disconnect switch.

q

Hanger brackets.

q

Controls enclosure for field mounted

controls.

q

Dust tight enclosure seal.

Seismic Certification:

q

SSI (Standard)

q

OSHPD

q

Special Features: ______________ .

DIMENSION "L"

1 or 2 row coils L=5" (127)

3 or 4 row coils L=7 1/2" (191)

*

Maximum airflow limit is based upon 1.5" w.g. (373 Pa) max. differential pressure signal from Diamond Flow Sensor.

Unit

Size

Airflow Range*

cfm (l/s)

W

H

Inlet Size

Coil Connections

1 Row 2 Row 3 Row 4 Row

4

0 – 225 (0 – 106) 10 (254)

10 (254)

3 7/8 (98) Round

1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

5

0 – 400 (0 – 189) 10 (254)

10 (254)

4 7/8 (124) Round

1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

6

0 – 550 (0 – 260) 10 (254)

10 (254)

5 7/8 (149) Round

1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

7

0 – 800 (0 – 378) 12 (305) 12 1/2 (318)

6 7/8 (175) Round

1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

8

0 – 1100 (0 – 519) 12 (305) 12 1/2 (318)

7 7/8 (200) Round

1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

9

0 – 1400 (0 – 661) 14 (356) 12 1/2 (318)

8 7/8 (225) Round

1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

10

0 – 1840 (0 – 868) 14 (356) 12 1/2 (318)

9 7/8 (251) Round

1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

12

0 – 2500 (0 – 1180) 18 (457) 12 1/2 (318) 12 15/16 x 9 13/16 (329 x 249) Oval 1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

14

0 – 3125 (0 – 1475) 24 (610) 12 1/2 (318) 16 1/16 x 9 13/16 (408 x 249) Oval

1/2 (13) 7/8 (22) 7/8 (22) 7/8 (22)

16

0 – 3725 (0 – 1758) 28 (711) 12 1/2 (318) 19 3/16 x 9 13/16 (487 x 249) Oval

7/8 (22) 7/8 (22) 7/8 (22) 7/8 (22)

24 x 16

0 – 8330 (0 – 3931) 38 (965)

18 (457)

23 7/8 x 15 7/8 (606 x 403) Rect.

7/8 (22) 7/8 (22) 1 3/8 (35) 1 3/8 (35)

Listed