Falcon II RJ-8000 Operation Instructions

42

AP-75080, Rev. 1.1, 04/12/02

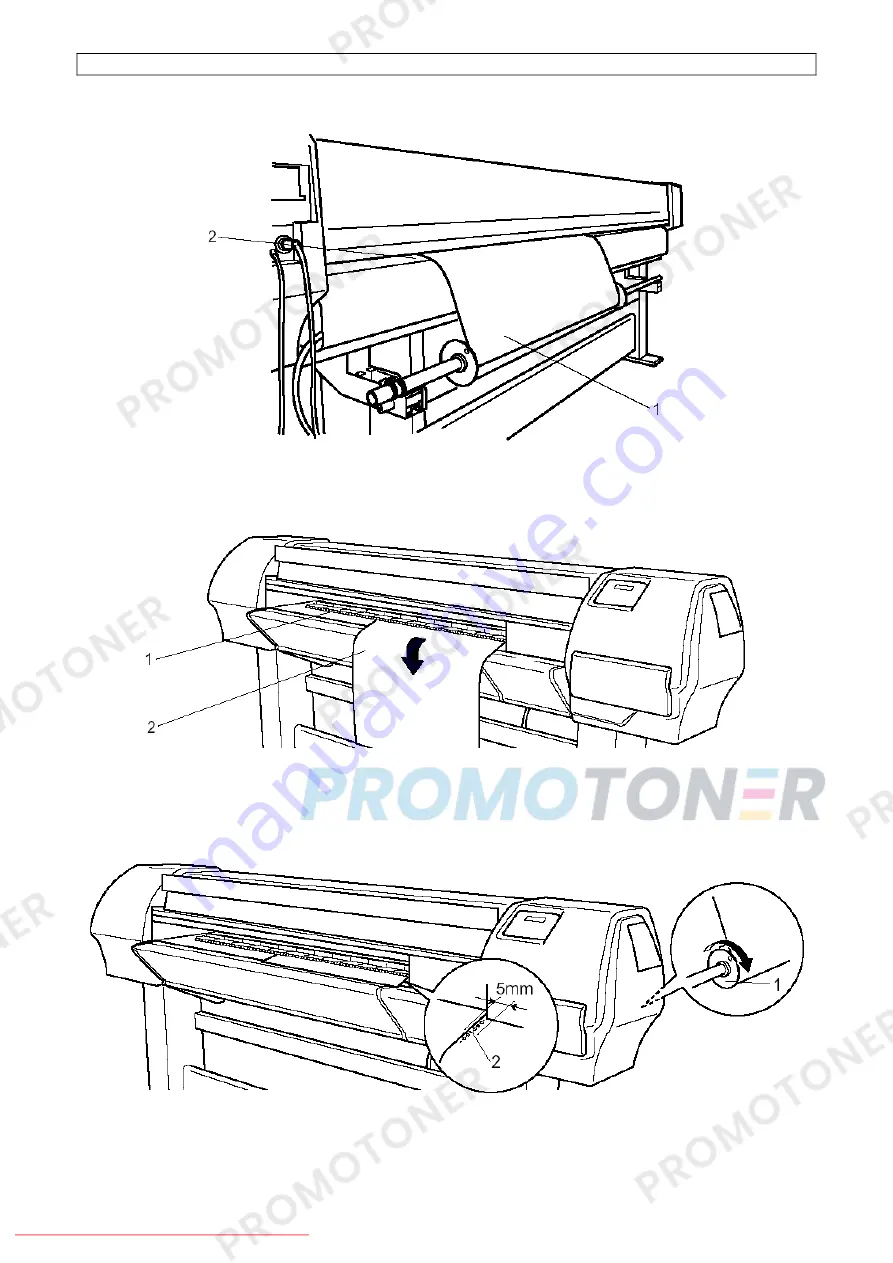

Step 6 :

Load the roll media into the insertion slot at the back of the printer. If there is a part not wounded

tightly on the end of the roll media, wind it tightly and then (re)load it.

1 = Roll media

2 = Insertion slot

Step 7 :

Pull the roll media about 1 m from the front media feed slot which is located inside the front

cover.

1 = Insertion slot

2 = Roll media

Step 8 :

While holding down the end of the media, hold the scroller and roll out a bit of the media.

Remove slack and skewness, then align the right edge of the roll media parallel with the media

loading position.

1 = Scroller

2 = Media loading position

Downloaded From ManualsPrinter.com Manuals