VJ-2606 INSTALLATION MANUAL

7

VJ2606E-I-01

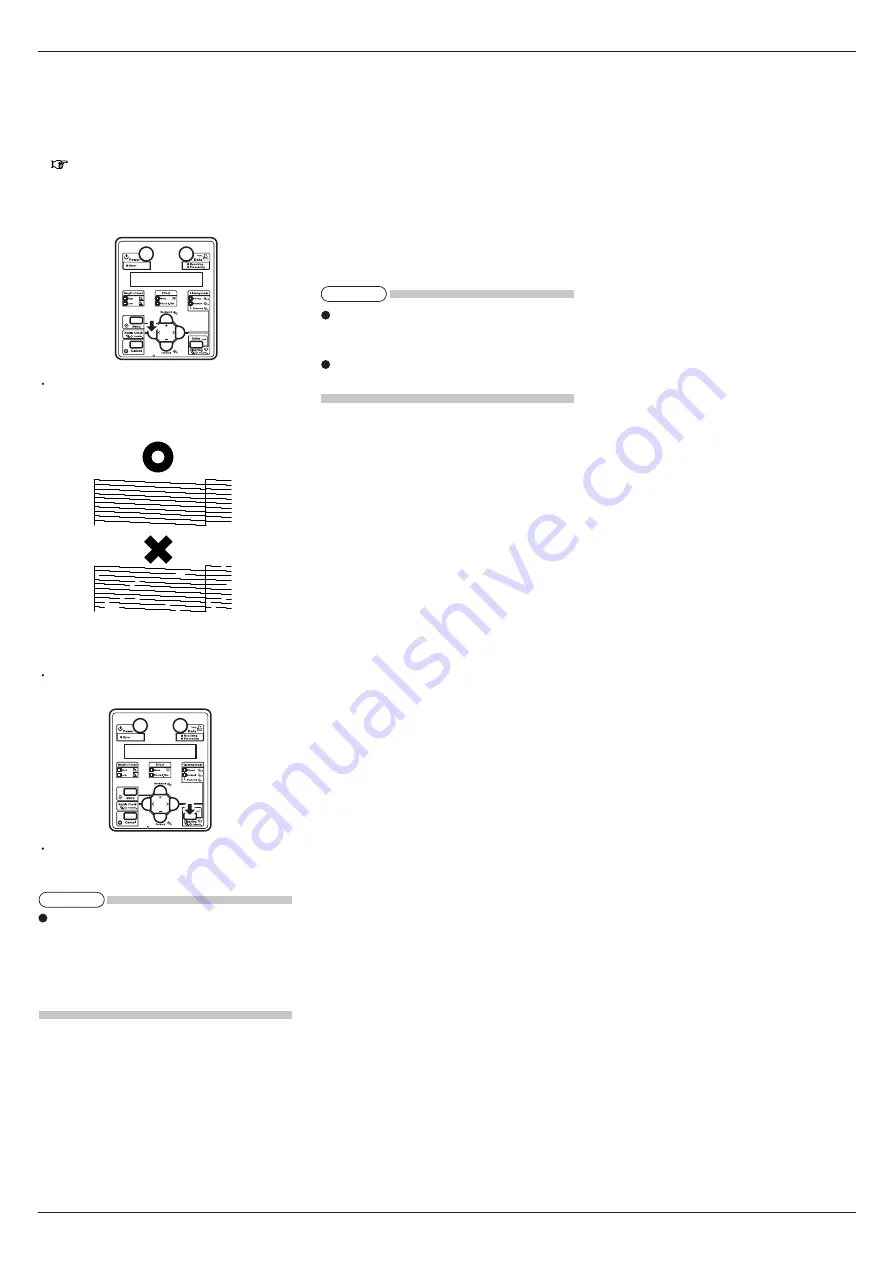

9 Checking printing conditions

Check the condition of the print head after the ink re-

plenishment.

1. Turn ON the printer and load the roll media.

7 Loading the roll media

2. Confirm that the printer functions normally.

3. Press the [<] key on the operation panel for two

seconds or more.

Nozzle check printing starts.

4. Check the sample print for blurred or missing

parts in the check pattern.

5. If the nozzle check result indicates that there is a

problem such as mentioned above in the check pat-

tern, clean the head.

Press and hold the [Cleaning] key on the operation

panel for two seconds or more.

"Cleaning **%" is displayed on the operation panel.

6. Head cleaning starts.

If one time of head cleaning was not enough to re-

move blurred or missing parts in the check pattern,

perform powerful cleaning.

If those problems above were not improved after a

few times of head cleaning, refer to the Operation

Manual "7 Troubleshooting" and perform required

procedures.

7. Perform nozzle check again and check the condi-

tion of the print head.

10 Manual composition

This product includes the following three manuals.

Installation Manual (this manual)

This manual explains the procedures of unpacking, in-

stalling, and the basic set up.

Quick Reference

Quick Reference is excerpts of functions used daily.

Operation Manual (CD-ROM)

The Operation Manual explains the basic installation,

daily use and applicable functions.

The Operation Manual of this product is created

with the HTML format and can be viewed using

browsers such as Internet Explorer.

Refer to Quick Reference "5.5 Using Operation

Manual CD" for viewing the Operation Manual.

TIP

NOTE