VJ-2606 INSTALLATION MANUAL

3

VJ2606E-I-01

1

2

1

1

3

4

3

4

1

2

2

2

1

1

1

1

2

e

g

d

c

b

f

a

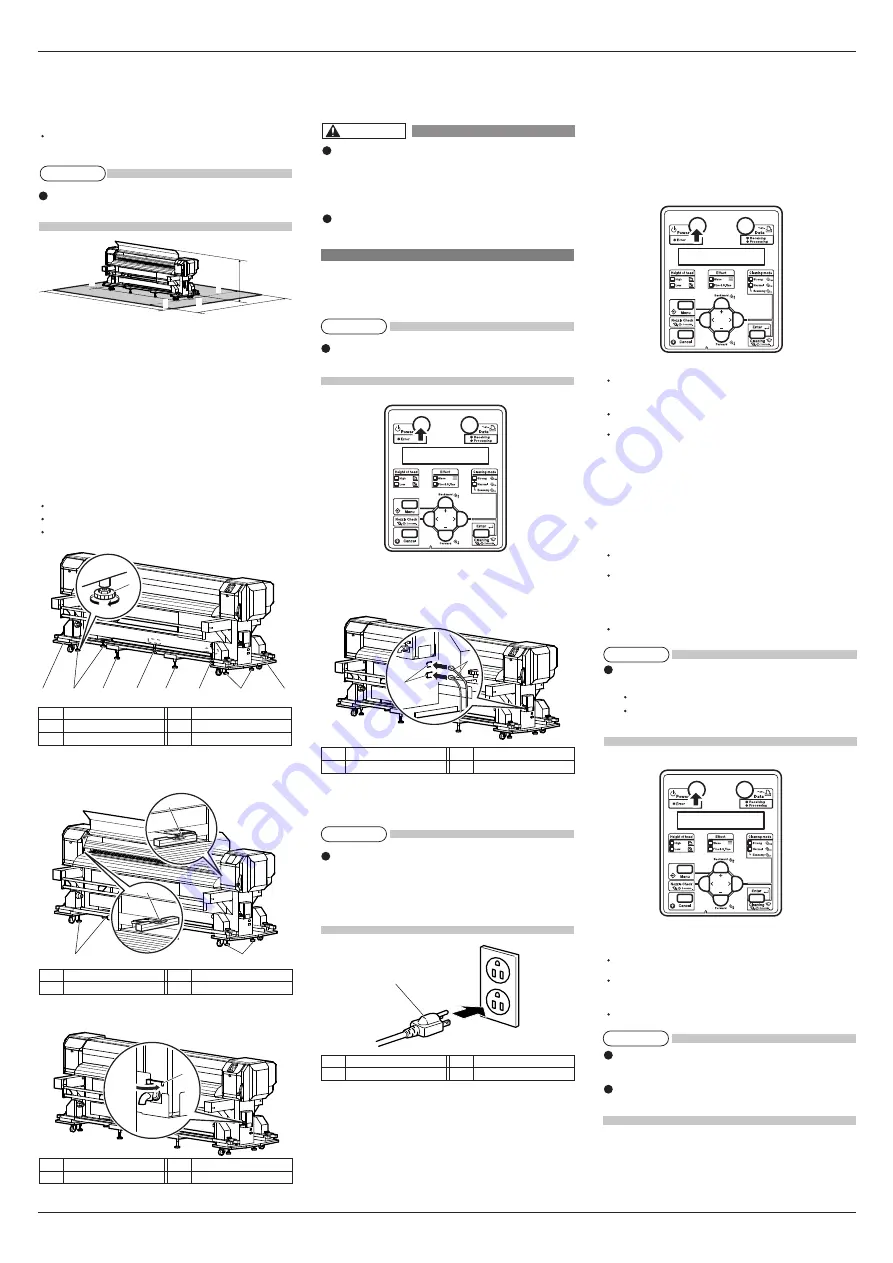

3.1.2 Installation space

Install on a level floor which meets the following con-

dition.

It has enough strength to support the weight of the

printer and the stand.

For the weight of the printer and the stand, refer to

the Operation Manual.

a = 650 mm

b = 1,000 mm

e = 1,250 mm

c = 1,000 mm

f = 5,200 mm

d = 1,000 mm

g = 2,950 mm

3.2 Installation procedure

Install this product to the installation place in accord-

ance with the list shown below.

1. Carry the printer to the installation place.

2. Turn the following adjusters in the direction as

shown below to prevent the printer from moving.

Stands: adjusters (4)

Winding units: adjusters (2)

Feed units: adjusters (2)

3. Set the spirit level on the right and left platens and

adjust so that the printer stays flat.

4. Confirm that the waste fluid valve is closed.

4 Connecting the power cable

This section explains how to connect the power cable.

Make sure that the included power ca-

ble is used.

If other power cables are used, it may

cause an electric shock or fire.

Do not use a damaged power cable. It

may cause an electric shock or fire.

Follow the steps below to connect the power cable.

1. Confirm that the product is turned OFF.

If the [Power] key is pressed, the product is turned

ON. Press the key again, and turn OFF the power.

2. Connect the power cables (x 2) to the AC inlets (x 2)

on the right of the product.

3. Correctly insert the power cable plug into the power

socket.

To use the two power cables plugged in the inlets,

a total capacity of 24 A or over is required. If the

power source cannot supply the required capacity,

plug the two power cables in the different power

sources respectively.

5 Turning the power ON/OFF

This section explains how to turn ON/OFF the printer.

5.1 Turning the power ON

Follow the procedure below to turn ON the printer.

1. Press the [Power] key on the operation panel to

turn ON the printer.

The Power lamp on the operation panel lights up

in green.

The printer starts initial operation.

When the initial operation is complete, the printer

enters normal status.

5.2 Turning the power OFF

Follow the procedure below to turn OFF the printer.

1. Regarding the operating condition of the printer,

confirm the following.

Printing or other operations are not in progress.

The operation panel is in normal status.

2. Press the [Power] key on the operation panel to

turn OFF the printer.

The Power lamp on the operation panel turns OFF.

If the operation panel is in the following status, the

power is ON.

The [Power] key is pressed in.

The Power lamp lights up in green.

Press the key once again and turn OFF the power.

3. The printer starts operating to turn the power OFF.

The operation panel displays "Power Off".

All the lamps on the operation panel and the LCD

monitor are turned OFF.

The printer automatically turns the power OFF.

After turning OFF the printer, wait for 10 seconds

or longer to turn it ON again.

When not using the printer for a long period, push

the media loading lever to the back.

4. When you will not use the printer for a long period

of time, raise the media loading lever.

No.

Name

1

Adjuster

3

Winding unit

No.

Name

2

Stand

4

Feed unit

No.

Name

1

Spirit level

No.

Name

2

Adjuster

No.

Name

1

Waste fluid valve

No.

Name

1

AC inlet

No.

Name

2

Power cable

No.

Name

1

Power cable

WARNING

NOTE

NOTE

NOTE

NOTE

NOTE