VJ-2606 INSTALLATION MANUAL

VJ2606E-I-01

4

1

2

3

4

4

1

2

1

2

3

1

2

3

1

2

3

4

4

1

2

1

7

6

5

4

3

2

6 Installing the ink cartridge

This section explains how to install ink cartridges.

Follow the steps below to install ink cartridges.

1. Turn ON the product.

The printer starts the initializing operation.

After the initial operation is complete, "Start Ink

Charge ->E" is displayed on the operation panel.

2. Press the [Enter] key on the operation manual.

The cleaning fluid which is filled at the factory

shipment is ejected.

After the cleaning fluid is discharged, "Wash Retry?

No" is displayed on the operation panel.

When cleaning the head before ink filling, select "Yes"

to press [+] or [-] keys on the operation panel.

Then press [Enter] key and clean the head.

3. Press the [Enter] key on the operation manual.

"Insert InkCartridges" is displayed on the opera-

tion panel.

4. Take out the ink cartridge from the bag and shake

it gently two to three times before installing.

Slots for ink cartridges are specified depending on

the colors of the ink cartridge.

Match the mark on each slot with the color of the

ink cartridge.

Install the ink cartridges with mark facing to the

product.

Insert the cartridge all the way into the product.

"Ink Refill **%" is displayed on the operation

panel and ink replenishment starts.

The ink replenishment takes about twelve minutes.

Ink filling operation and pause operation are re-

peated during the ink replenishment.

When "100%" is displayed, the ink replenishment

is complete.

After the ink replenishment is complete, "SubTank

Refill" is displayed on the operation panel, and the

SubTank Refill is started.

After the SubTank Refill is complete, "Media End"

is displayed on the operation panel.

If the Nozzle check printing is performed immedi-

ately after the ink replenishment is complete, the

following results may occur.

Printed line becomes blurred.

The data is not partially printing.

In such cases, follow the Operation Manual "6.2.3

Head cleaning" and charge a small amount of ink.

Then, check the printing result.

If there is no improvement in the print result even

after refilling a small amount of ink, leave the

printer for one hour or more, and refill a small

amount of ink again.

If there is still no improvement, contact MUTOH

local dealer.

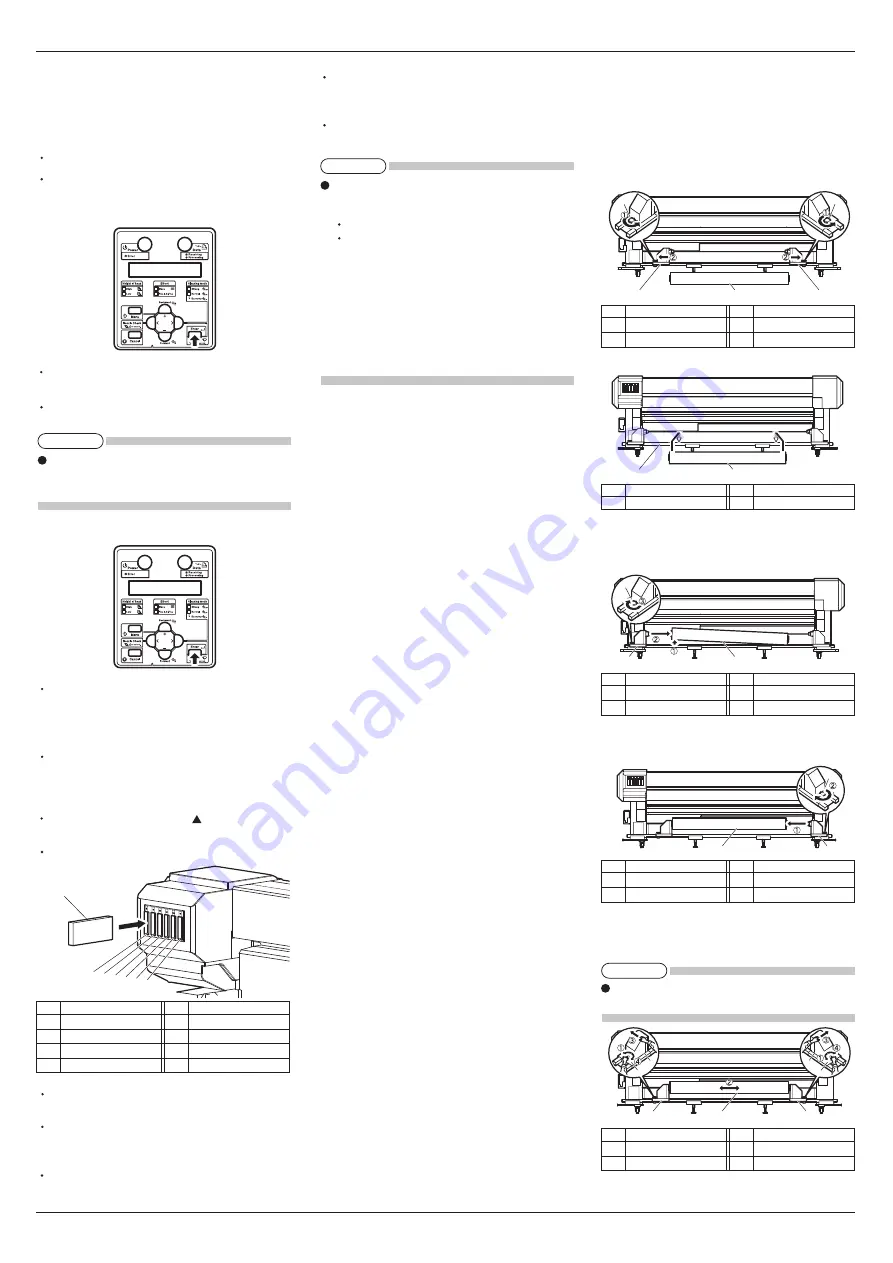

7 Loading the roll media

This section describes how to load roll media.

Place the roll media in the center of the printer.

Follow the steps below to load roll media.

1. Loosen the fixing knobs of the right and left rear

feed units, and stretch the knobs wider than the

width of the roll media.

2. Place the media on the rail of the feed unit.

3. Lift the left side of the roll media (looking from

the rear), attach it to the feed unit, and fix it with

the fixing knob.

4. Set the other side of the roll media in the same

way as in step 3.

5. Loosen the fixing knobs of the right and left feed

units, move the roll media to the center and tighten

the knobs.

Be sure to press the feed units against the printer

while locking them.

(Continue to next)

No.

Name

1

Rail of the feed unit

No.

Name

2

Roll media

No.

Name

1

Feed unit (Right)

2

Roll media

No.

Name

3

Fixing knob

No.

Name

1

Feed unit (Left)

2

Feed unit (Right)

No.

Name

3

Roll media

4

Fixing knob

No.

Name

1

Feed unit (Left)

2

Feed unit (Right)

No.

Name

3

Roll media

4

Fixing knob

No.

Name

1

Feed unit (Left)

2

Roll media

No.

Name

3

Fixing knob

No.

Name

1

Ink cartridge

2

Ink cartridge slot K

3

Ink cartridge slot C

4

Ink cartridge slot M

No.

Name

5

Ink cartridge slot Y

6

Ink cartridge slot Lc

7

Ink cartridge slot Lm

NOTE

NOTE

NOTE