VJ-2606 INSTALLATION MANUAL

5

VJ2606E-I-01

1

2

1

5mm 5mm

5mm

5mm

2

1

2

1

2

1

1

2

3

4

4

1

2

1

1

2

1

1

1

2

1

2

3

1

2

3

1

2

3

1

2

3

(Cont'd)

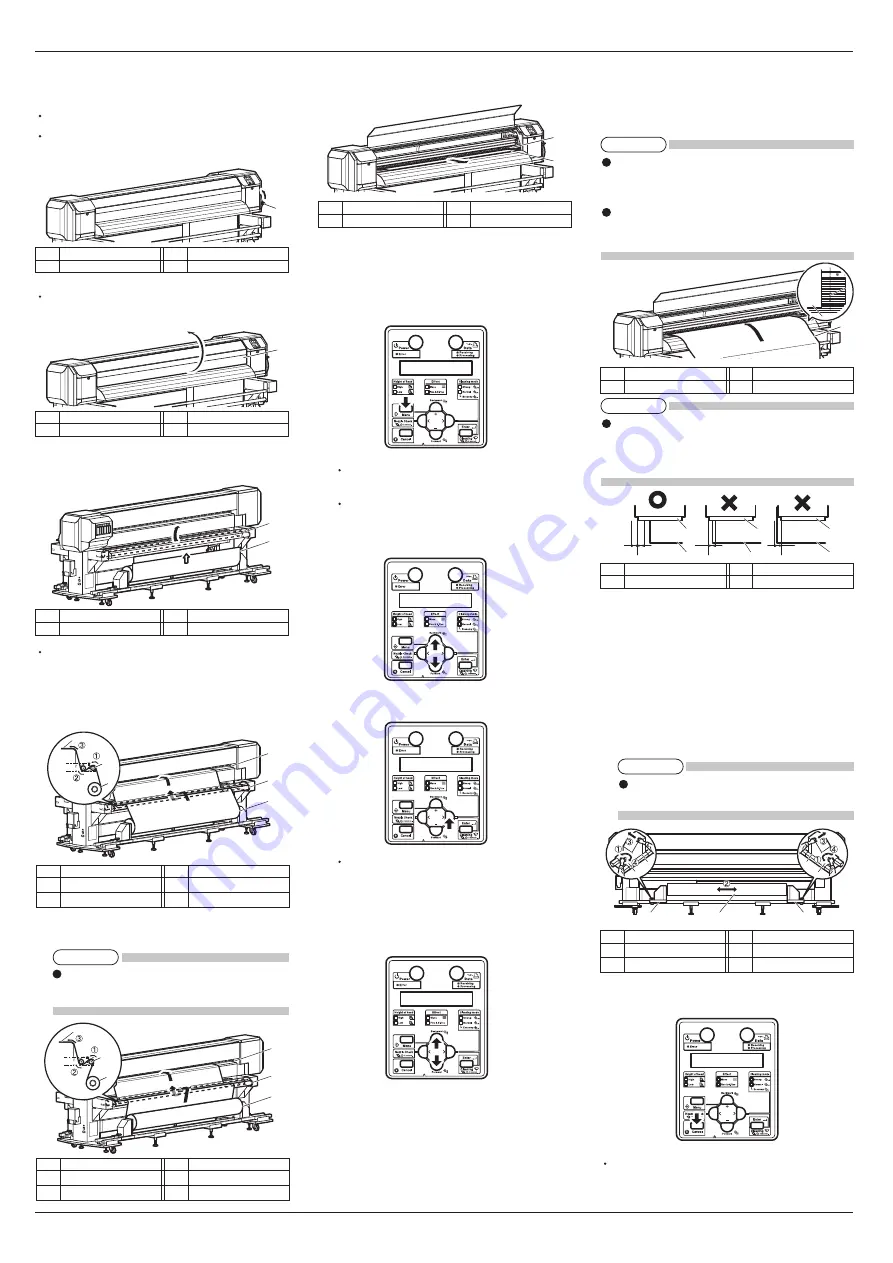

6. Turn the printer ON.

The printer starts initial operation.

"Media End" is displayed on the operation panel.

7. Raise the media loading lever.

"Lever Up" is displayed on the operation panel.

8. Open the front cover.

9. Lift the tension roller on the rear of the printer us-

ing your hands.

The roll media is fed.

10. Pass the roll media through the tension roller first,

and insert it into the media feed slot.

a. When using roll media with the printing side

facing outwards

b. When using roll media with the printing side

facing inwards

Any problems caused by using roll media with

the printing side facing inwards cannot be cov-

ered by the warranty.

11. Pull the roll media approximately 1 m out of the

media feed slot, which is inside the front cover.

12. Display the Manual reel menu on the operation

panel.

a. Press the [Menu] key on the operation panel.

Press the [+] key or [-] key to select "Menu6:

Manual Reel >".

The display enters the Setup menu.

b. Press the [+] key or [-] key to select "Menu6:

Manual Reel >".

c. Press the [>] key on the operation panel.

"<- Order [T-up] Reverse ->" is displayed on

the operation panel.

13. Press the [+] key or [-] key to select "<- Order

[Feed] Reverse ->".

14. While holding the front end of the roll media, wind

the media back for a short distance by pressing the

[>] key on the operation panel so that the media is

not slack or slanted.

If you release your grip on the roll media while it

is being wound, the media may slip off the media

feed slot and fall behind the printer.

Make sure that the right end of the roll media does

not go beyond the media loading mark. It may af-

fect print quality.

When loading roll media, set each side of the media

at least 5 mm away from the edges of the pressurizing

roller. Failing to do so may cause the media to slip

or wrinkle while being printed on.

15. If the distance between the edge of the roll media

and the pressurizing roller is less than 5 mm, follow

the procedure below to adjust the position of the

roll media.

a. Loosen the fixing knobs of the right and left feed

units, and move the roll media to the right or left.

b. After moving the roll media, tighten the fixing

knobs.

Be sure to press the feed units against the print-

er while locking them.

16. Press the [Cancel] key on the operation panel.

The operation panel returns to Normal.

(Continue to next)

No.

Name

1

Roll media

No.

Name

2

Media loading mark

No.

Name

1

Roll media

No.

Name

2

Pressurizing roller

No.

Name

1

Feed unit (Left)

2

Feed unit (Right)

No.

Name

3

Roll media

4

Fixing knob

No.

Name

1

Roll media

No.

Name

2

Media feed slot

No.

Name

1

Media loading lever

No.

Name

1

Front cover

No.

Name

1

Roll media

No.

Name

2

Tension roller

No.

Name

1

Roll media

2

Tension roller

No.

Name

3

Media feed slot

No.

Name

1

Roll media

2

Tension roller

No.

Name

3

Media feed slot

NOTE

NOTE

NOTE

NOTE