Total additional refrigerant charge amount (R) is

equal to the sum of R1, R2 and R3, calculate the

amount of refrigerant to be charged according to the

formula below:

R (kg) = R1 + R2 +R3.

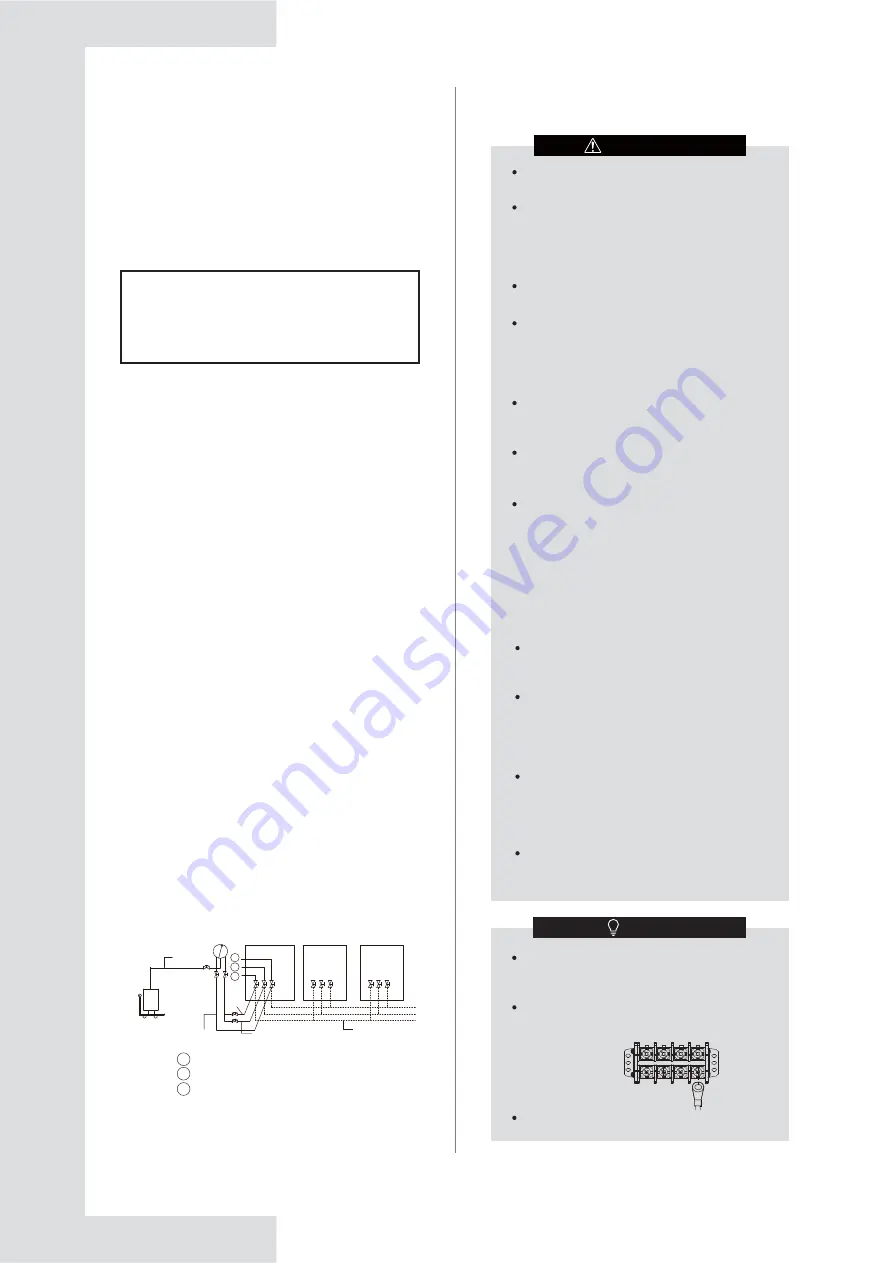

Fig. 5-19

Master unit

Slave unit

Slave unit

Note: The additional refrigerant charge amount (R3) is

obtained by summing the additional charge

requirements for each of the outdoor and indoor liquid

pipes, as in the following formula, where L1 to L8

represent the equivalent lengths of the pipes of different

diameters. Assume 0.5 m for the equivalent pipe length

of each branch joint.

#*$###%£

|` ¤

_` ¤ `{

{ ¤

+`_¤{

`_¤ |

|

¤|

{ `+¤`

X X|¤

0.680

The procedure for adding refrigerant is as follows:

1. Calculate additional refrigerant charge R (kg).

2. Place a tank of R410A refrigerant on a weighing

scale. Turn the tank upside down to ensure refrigerant

is charged in a liquid state. (R410A is a blend of two

different chemicals compounds. Charging gaseous

R410A into the system could mean that the refrigerant

charged is not the correct composition).

3. After vacuum drying, the manifold should still be

connected to the master unit stop valves.

4. Connect the manifold from the pressure gauge to the

R410A refrigerant tank.

5. Open the valve where the hose (hose a) meet the

pressure gauge, and open the refrigerant tank slightly

to let the refrigerant eliminate the air.

Caution: open the tank slowly to avoid freezing your

hand.

6. Set the weighing scale to zero.

7. Open the manifold valves to begin charging

refrigerant.

8. When the amount charged reaches R (kg), close the

manifold valves. If the amount charged has not

reached R (kg) but no additional refrigerant can be

charged, close the manifold valves, run the outdoor

units in cooling mode, and then open the manifold

valve A

,

C and D. Continue charging from the service

port of low pressure stop valve until the full R (kg) of

refrigerant has been charged, then close the manifold

valve A

,

C and D. Note: Before running the system, be

sure to complete all the pre-commissioning checks and

be sure to open all stop valves as running the system

with the stop valves closed would damage the

compressor.

A

B C

D

E

3

2

1 Low pressure gas pipe stop valve

High pressure gas pipe stop valve

Liquid pipe stop valve

Pressure gauge

Hose a

Hose d

Hose c

Hose b

Field piping

Weighing scale

R410A

refrigerant tank

3

2

1

WARNING

5.10 Electrical Wiring

5.10.1 Electrical wiring precautions

Take note of the risk of electric shocks during

installation.

All the electric wires and components must

be installed by an installation personnel with

the proper electrician certification, and the

installation process must comply with the

applicable regulations.

Use only wires with copper cores for the

connections.

A main switch or safety device that can

disconnect all polarities must be installed,

and the switching device can be completely

disconnected when the corresponding

excessive voltage situation arises.

Wiring must be carried out in strict

accordance with what is stated in the product

nameplate.

Do not squeeze or pull the unit connection,

and make sure the wiring is not in contact

with the sharp edges of the sheet metal.

Make sure the grounding connection is safe

and reliable. Do not connect the earth wire to

public pipes, telephone earth wires, surge

absorbers and other places that are not

designed for grounding. Improper grounding

may cause electric shock.

Make sure the fuses and circuit breakers

installed meet the corresponding

specifications.

Make sure an electric leakage protection

device is installed to prevent electric shocks

or fires.

The model specifications and characteristics

(anti high-frequency noise characteristics) of

the electric leakage protection device are

compatible with the unit to prevent frequent

tripping.

Before power on, make sure the connections

between the power cord and terminals of the

components are secure, and the metallic

cover of the electric control box is closed

tightly.

WARNING

If HT hydro module connects to the system,

please refer to the installation manual of the HT

hydro module.

If the power supply lacks N phase or there is

an error in the N phase, the device will

malfunction.

The N phase must connect to mark N of the

terminal block, or the device will malfunction.

Do not share the same power supply line with

other devices.

NOTE

/

/

/

1

1

25