PAGE 44 — DCA1100SSC 60 HZ GENERATOR • OPERATION MANUAL — REV. #1 (01/17/18)

AIR REMOVAL (FUEL INJECTION SYSTEM)

If air enters the fuel injection system of a diesel engine,

starting becomes impossible. After running out of fuel,

or after disassembling the fuel system, bleed the system

according to the following procedure. See the

Cummins

Operation and Maintenance Manual for details.

Drive Belt Tension

A slack drive belt may contribute to overheating, or to

insufficient charging of the battery, adjust drive belt in

accordance with the John Deere Operator's manual.

Drive Belt inspection

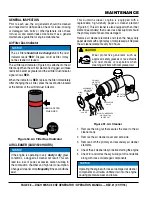

1. Inspect the drive belt (Figure 64) for damage and wear.

Horizontal (across the belt) cracks are acceptable.

Vertical (direction of belt ribs) cracks that intersect with

horizontal cracks are not acceptable.

Figure 64. Drive Belt Inspection

2. If the drive belt is frayed, punctured, or material is

missing

DO NOT use drive belt.

NO

NO

MAINTENANCE

GENERATOR STORAGE

For long term storage of the generator the following is

recommended:

Drain the fuel tank completely. Treat with a fuel stabilizer

if necessary.

Completely drain the oil from the crankcase and refill if

necessary with fresh oil.

Clean the entire generator, internal and external.

Cover the generating set and store in a clean, dry place.

Disconnect the battery.

Make sure engine coolant is at proper level.

If generator is mounted on a trailer, jack trailer up and

place on blocks so tires do not touch the ground or block

and completely remove the tires.