VOXI User’s Guide

7

3.

Installation

WARNING !

•

The VOXI is currently not certified for use in hazardous gas locations. Install this unit only

in an area known to be free of combustible gases and vapors.

•

Before installation, ensure that all power is disconnected.

•

Before removing the monitor cover for service, disconnect the power supply and ensure

that the area free of combustible gases and vapors.

•

For European locations, installation must comply with EN-60079-14.

•

The instrument should be calibrated after installation before initial use and checked by

exposing it to a known concentration calibration on a regular basis.

•

Remove the sensor only if necessary for repair. Zero and span calibration are required once

the sensor is moved.

3.1 Mounting

3.1.1 Mounting Location

For safety and ease of maintenance, the VOXI should be installed in a non-hazardous-gas

location.*

1

Extension tubing of up to 100 feet (30 m) can be attached to the inlet to allow remote

mounting if the sampling location contains flammable or toxic gas mixtures.

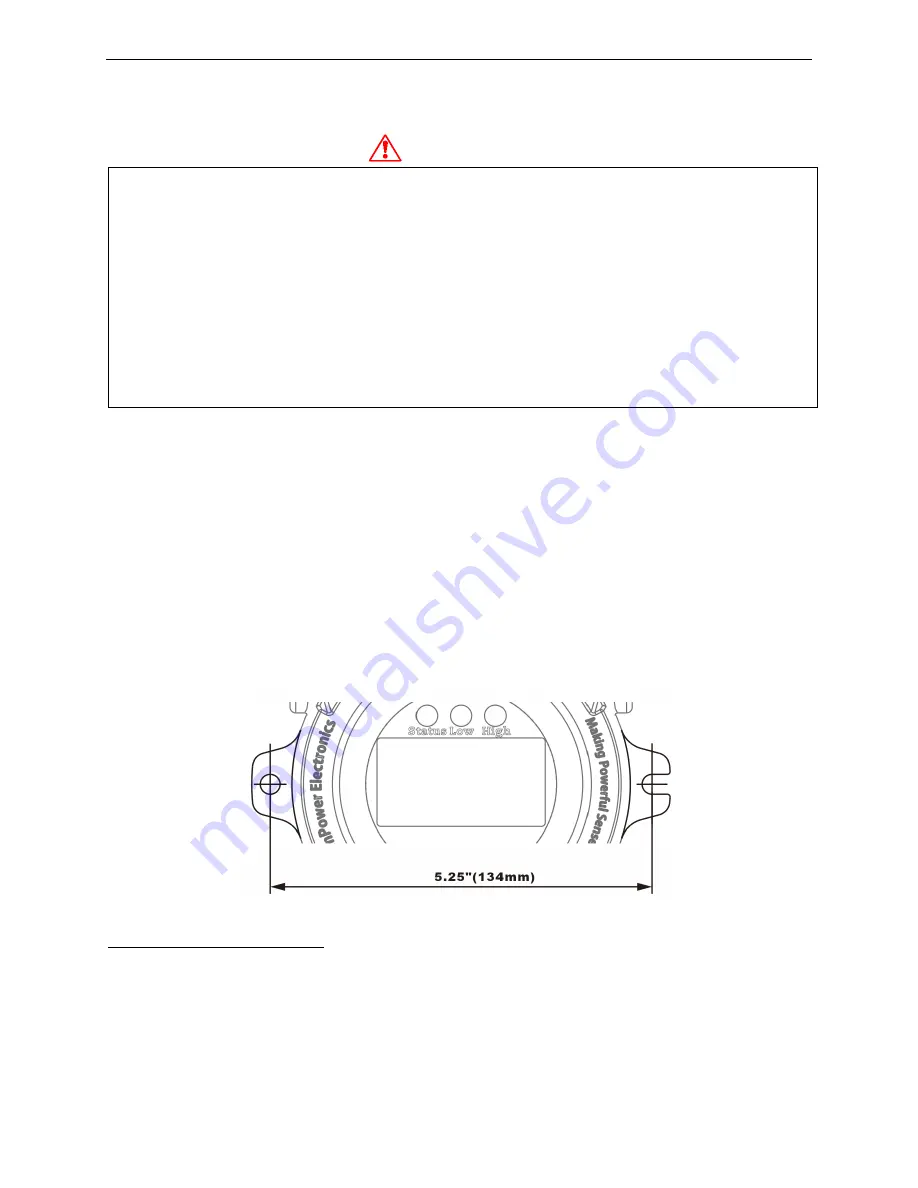

3.1.2 Mechanical Mounting Options

The VOXI is designed for wall mount or pole mount using the screw-holes provided, centered

5.25 inches or 134 mm apart. If mounted outdoors, ensure that the gas inlet is directed

downwards to minimize the chance of precipitation being drawn into the PID.

*

1

Future VOXI versions that have certifications will be able to be installed and operated in hazardous-gas

locations, but because the housing cannot be opened for service in the presence of flammable gases, the VOXI is

easier to maintain if installed in a non-hazardous location or one that can be vented to remove hazardous gases

before opening the housing.