D. DRILLING IN WET CONDITIONS

The Uni-Drill is fitted with adjustable scrapers for the press wheels. Wet Soil will usually

build up to about one inch on any wheel. Adjust the scraper so as to knock off the excess

soil that would build up over the normal amount of soil that sticks to the press wheels.

Leave a gap of 15 to 20 mm between the scraper and the press wheel. Never reverse the drill

with the seed tube coulters in the ground as this would block the seed outlets with soil.

Where there are very wet pockets of soil in some fields, the road wheels can be used to

slightly raise the drill out of the ground thus assisting the drill to drill high; always keep the

drive wheel in contact with the ground. Speed is the biggest aspect, below 7 km/hr the disc

coulters will tend to block above 9 km/hr is the optimum for drilling.

E. DRILLING INTO STRAW INCORPORATED SOIL AND

TRASHY

CONDITIONS

In heavy trash conditions it may be necessary to raise the tip of the seed tube coulter so that

the disc will cut through the trash before the coulter opens the slit. In heavy maize trash,

especially in the direct drill or no-till situation, it may be necessary to raise the tip of the

seed tube coulter 30 to 40 mm above the edge of the disc. The discs cut through the trash

very positively. The weight of the press wheels keep the discs anchored and do not allow the

discs to ride out of the soil, even when there is a lot of trash present. Bulldozing normally

occurs when a disc meets trash, tries to ride up over the trash, then pushes it in front of the

disc, thus causing bulldozing and blockages. If this happens it is usually due to the soil

underneath being too loose. The drill will cut cleanly through, given that it has something to

“bite on”. Consolidating the field with either rollers or a land packer, sufficient to allow the

drill’s discs to turn, will usually cure the problem. A speed of 9 - 11 Km/hr works, 7 - 8

Km/hr doesn’t.

The trash itself especially chaff, on decaying, produces acids, toxins, etc., which tend to

damage or kill the germinating seed. If the trash is mixed with the soil and consolidated

tightly to give a good straw/soil contact then the soil will absorb the toxins as they are

formed , before they can harm the germinating seedlings. The press wheels on the

UNIDRILL consolidated the trash, soil and seed in exactly the right manner to give very

healthy plant stands even in the heaviest incorporated residues. If straw is incorporated

into the soil to leave a loose fluffy seedbed then it must be consolidated first using either a

roller or land packer, etc., before drilling.

F. MINIMUM TILLAGE AND DIRECT DRILLING

In certain soils, especially if they contain stone or brash, it is recommended that the top 1”

or 2” should be cultivated or scratch tilled. This will encourage the germination of volunteer

cereals and weed seeds. It will also help to level out the tramline and wheeled tracks. Also if

stones are left undisturbed in the top layer, they become embedded and the disc will ride

from stone to stone without getting good penetration.

In soft field conditions it is essential to set the discs deep enough to cut through all the matt

or surface trash. Seed will germinate and grow better when in contact with the soil. In wet,

soft conditions the disc may be set to penetrate deeper than required. As the drill moves

forward the seed is trapped by the sides of the slit and do not necessarily fall to the bottom

of the slit.

32

Operation

Summary of Contents for UNIDRILL 300

Page 1: ...August 2001...

Page 5: ...4 Safety Regulations...

Page 7: ...6 Warning Symbols 1...

Page 9: ...Safety Instruction Decals 8...

Page 10: ...Safety Instruction Decals 9 25...

Page 29: ...28...

Page 41: ...Maintenance Tyre pressure chart for 10 0 75 15 3 Vredestein Tyres 40...

Page 42: ...Optional Equipment Section 5 MS Flow Modulation 41...

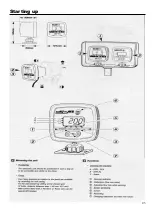

Page 44: ...Starting up 43...

Page 45: ...Starting up 44...

Page 46: ...Operation 45...

Page 47: ...Operation 46...

Page 48: ...Operation 47...

Page 49: ...Operation 48...

Page 50: ...Operation 49...

Page 51: ...50 D E...

Page 55: ...Dragarm Seeding Unit 47 48 54 Parts list...

Page 59: ...Drawbar and Rear Axle Assembly 58 Parts list 47 48 45 1 2 49 3 4 50 51 52 53 53 A B 55 54 35...

Page 61: ...Drive wheel Assembly 60 Parts list 26...

Page 63: ...Seed Box Assembly S900520 S901537 62 Parts list...

Page 65: ...Seed Box Drive Unit 64 Parts list...

Page 67: ...Multiplicator Parts list 66...

Page 69: ...MS Flow Modulation Parts list 1 3 2 7 10 8 9 11 6 5 4 15 14 12 13 68...

Page 71: ...Linak Actuator Tramline Mechanism Parts list 1 5 2 7 6 4 3 9 8 70...

Page 73: ...Seedbox Metering Parts Parts list 10 12 11 8 6 5 4 3 9 2 1 7 72...

Page 75: ...SPI Vertical Lift Marker 74 Parts list...

Page 77: ...Moore Vertical Lift Marker 17 13 16 47 48 Complete disc hub assembly 14 15 74 Parts list...

Page 79: ...Electric Parts Sensors Parts list 1 4 3 2 76...

Page 86: ...Calibration Charts Calibration charts for Rape Barley Peas and Field Beans 83...

Page 87: ...Calibration Charts Calibration charts for Oats Mustard Phacelia and Radish 84...

Page 88: ...Calibration Charts Calibration charts for Lucern Linseed Rye grass and Clover 85...

Page 89: ...Notes 86...