49

7.1

Troubleshooting Guide

If a degradation in performance or other failures are experienced, check for these common issues:

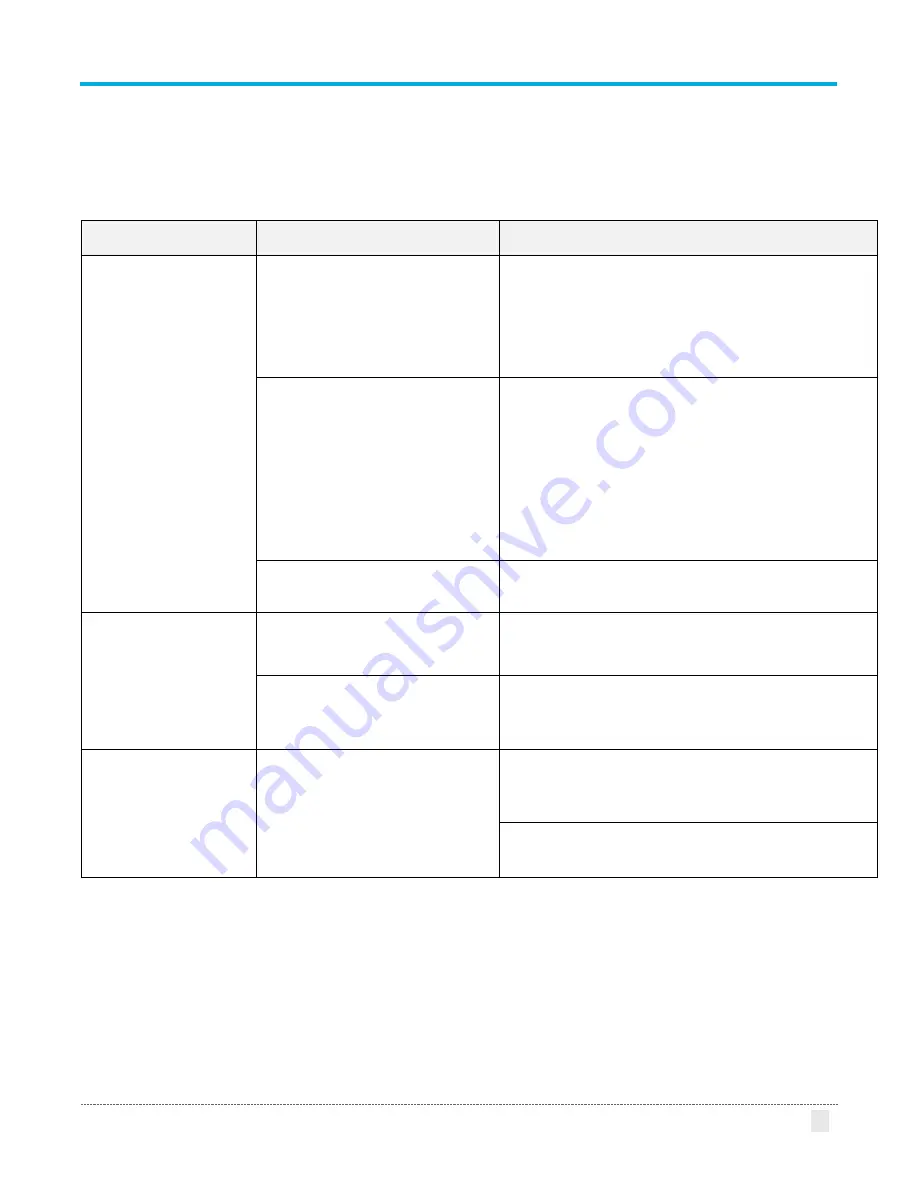

Problem/Symptom

Possible Cause

Solution/Suggestion

Axis not moving

Physical impediment.

•

Check physical state of positioner stack for:

o

Grease on the axis that isn’t moving.

o

Any other contamination on the axis.

o

Wire routing impediments.

o

Potential collisions preventing

movement.

Control cabling issue.

Ensure all cables and wiring are connected/plugged in

and do not have any shorts or breaks.

•

Check thermal clamp where In-Vacuum control

cable is clamped and make sure it isn’t clamped

too tight:

o

Remove clamp and check to see if axis

becomes operational.

o

Re-install clamp and do not torque

screws to more than 0.5 in-lbs.

Incorrect settings (open loop

only).

Confirm that settings are correct.

No encoder feedback

(incorrect feedback)

Cables are not properly

connected.

Check cables and plugs to ensure everything is

connected properly and do not have any shorts or

breaks.

Nanopositioner is not paired with

the correct controller (multi-stack

configuration).

If in a multi-stack configuration confirm that the

correct controller is being paired with the

nanopositioner.

Z-axis not moving up

Mass on top of positioner is too

heavy (100g-250g)

Mass (>100g) on top of the positioner, you may have

overloaded the z-axis. Reduce the mass on top of the

positioner.

Install the Low Force Spring Plunger and see if the

positioner can lift the mass.