AS 914 TI

User Manual

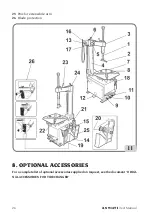

15

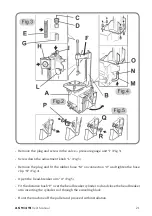

1.2.c. ELECTRICAL AND PNEUMATIC CONNECTIONs

The dimensions of the electric hook-up

used must be suitably sized in relation to:

• the electric power absorbed by the ma-

chine, indicated on its data plate (Fig. 1);

• the distance between the machine and

the power supply hook-up point, so that

voltage drops under full load do not exceed 4%

(10% during start-up) compared with the rated

voltage specified on the data plate.

- The operator must:

• fit a power plug on the power supply lead in

compliance with the relevant safety standards;

• connect the machine to its own electrical con-

nection - A, Fig. 1a - and fit a differential safety

circuit-breaker with 30 mA residual current;

• fit fuses to protect the power supply line, rated

as indicated on the general wiring diagram in

this manual;

• connect the machine to an industrial socket;

the machine must not be connected to domestic

sockets.

An effective grounding connection is essential for correct operation of the machine.

NOTICE

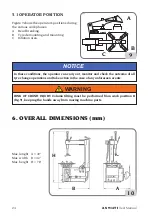

Make sure the available pressure and the rendered capacity of the compressed air system

are compatible with those required for correct machine operation - see the “Technical Data”

section. For correct machine operation, the compressed air supply line must provide a

pressure range from no less than 8.5 bar to no more than 16 bar and guarantee an air flow

rate greater than the average consumption of the machine, which is equal to 187 Nl/min.

For correct equipment operation, the air produced must be suitably treated (not

above 5/4/4 according to IsO 8573-1)

NOTICE

1a

A

ISO9001

Code

Serial N.

X-XXXXXXXX/XX - XX

XXXXXXXXX

QUAL. SYS. CERTIFIED

ANNO DI COSTRUZIONE /

MANUFACTURED

Mod.

V

A

kW

Hz

Ph

bar7psi

Port.max

1