PRODUCT APPLICATION SPECIFICATION

THIS DOCUMENT CONTAINS INFORMATION THAT IS PROPRIETARY TO MOLEX ELECTRONIC TECHNOLOGIES, LLC AND SHOULD NOT BE USED WITHOUT WRITTEN PERMISSION

REVISION

DESCRIPTION

REVISED

APPLICATION SPECIFICATION FOR

MICRO-LOCK PLUS 2.0 SINGLE ROW

CHANGE NO.

682239

REVISED BY

SOKUMURA01

DATE

2021/02/09

DOC TYPE

DOC TYPE DESCRIPTION

DOC PART

SERIES

REV APPR BY AIDA

DATE

2022/06/30

PS

APPLICATION SPECIFICATION WORD

A03

505570

INITIAL RELEASE

CUSTOMER

DOCUMENT NUMBER

REVISION

SHEET

INITIAL DRWN KUSATO

DATE

2016/04/20

GENERAL MARKET

5055700001

E

9

OF

49

INITIAL APPR

TKANEKO

DATE

2016/04/21

PROCEDURE: 2090580010-ES TEMPLATE: 2090580010-PAS-A4 REVISION: A1

【

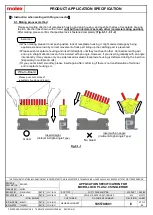

4. The confirmation items of crimping wire

】

4-1. The appearance before crimping

When using the loose terminals products before crimping, please make sure that there is no deformation of the

crimp terminal. If you find that the terminals are tangled, please do not remove them forcibly.

Please refer to sales drawing for product form and its dimensions.

4-2. The appearance after crimping

Confirmation items and crimping failure after crimping are shown as follows.

(Fig.4-1)

Please refer to ATS for specified crimp height, pull testing, and applicable wire specification.

①

No visible damage on terminal.

②

No visible damage or deformation on contact area.

③

All wire strands are in conductor barrel.

④

The insulator part of the electric wire is located in the intermediate position of

wire barrel and insulation barrel.

⑤

No damage on lance.

⑥

No damage on appearance. (Dirt / foreign objects)

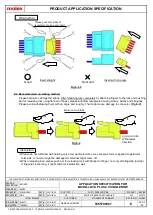

4-3. Crimping failure

Please be careful of the crimping failure as shown below.

It may affect the insertion to housing and affect a product function.

1. Bend up

It may deteriorate insertion to housing and terminal retention force or cause contact failure.

(Fig.4-2)

2. Bend down

It may deteriorate insertion to housing and terminal retention force or cause contact failure.

(Fig.4-3)

×

No Good

×

No Good

②

③

④

⑤

①

⑤

③

④

①②

Fig.4-1

Fig.4-2

Fig.4-3