PRODUCT APPLICATION SPECIFICATION

THIS DOCUMENT CONTAINS INFORMATION THAT IS PROPRIETARY TO MOLEX ELECTRONIC TECHNOLOGIES, LLC AND SHOULD NOT BE USED WITHOUT WRITTEN PERMISSION

REVISION

DESCRIPTION

REVISED

APPLICATION SPECIFICATION FOR

MICRO-LOCK PLUS 2.0 SINGLE ROW

CHANGE NO.

682239

REVISED BY

SOKUMURA01

DATE

2021/02/09

DOC TYPE

DOC TYPE DESCRIPTION

DOC PART

SERIES

REV APPR BY AIDA

DATE

2022/06/30

PS

APPLICATION SPECIFICATION WORD

A03

505570

INITIAL RELEASE

CUSTOMER

DOCUMENT NUMBER

REVISION

SHEET

INITIAL DRWN KUSATO

DATE

2016/04/20

GENERAL MARKET

5055700001

E

16

OF

49

INITIAL APPR

TKANEKO

DATE

2016/04/21

PROCEDURE: 2090580010-ES TEMPLATE: 2090580010-PAS-A4 REVISION: A1

6.

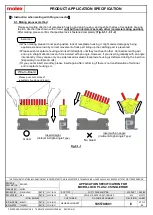

When checking harness after processing, please avoid bending wire excessively or with tension.

That might cause contact failure because force was added to terminal crimping part or receptacle

housing lance part.

7.

When having a conduction check, do not attach anything besides applicable mating connector.

That might cause contact failure because of transformation of terminal etc.

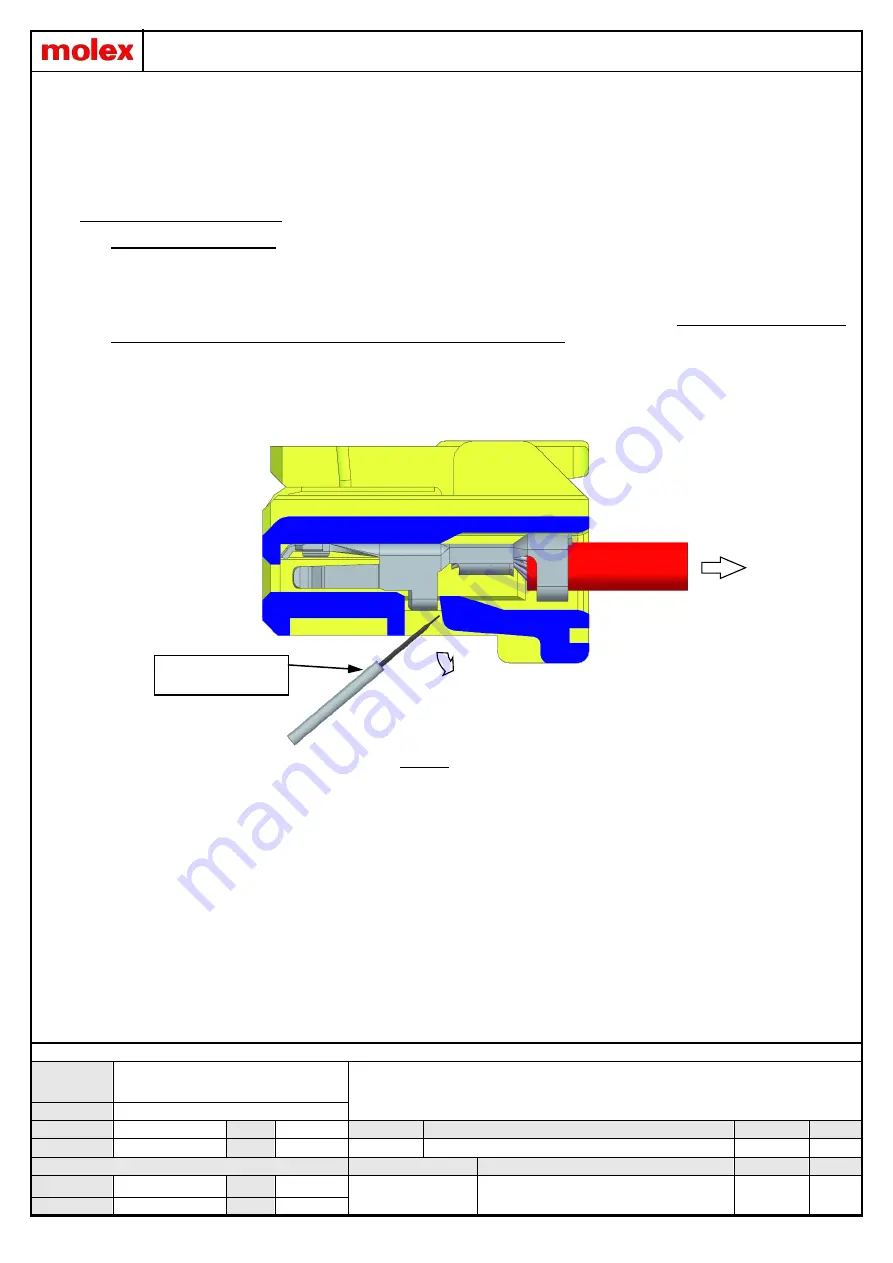

6-2. Repair of crimp terminal

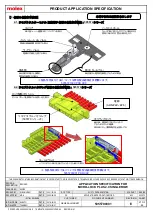

For receptacle terminal

When you withdraw the crimp terminal inserted once, please withdraw it with raising mold lance using

something sharp like needle.

However, mold lance is transformed by being raised. As strength of the transformed lance decreases extremely,

the terminal might come off easily from housing even if you insert it again. Therefore, please be sure to change

the receptacle housing to a new one when you repair crimp terminal. Also, please use an appropriate magnifying

glass and repair with caution.

(Fig.6-6)

※

Please avoid pulling off terminal by force.

※

When repairing, please be careful not to deform or scratch terminal lance.

Jig with sharp

end like needle

①

②

Fig.6-6