17

6-563.7

eleCTrICAl ConneCTIons

WARNING

1. Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage.

2. All appliances must be wired strictly in accordance with

wiring diagram furnished with the appliance. Any wiring

different from the wiring diagram could result in a hazard

to persons and property.

3. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

4. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% greater than or

5% less than the rated voltage.

1. Installation of wiring must conform with local building codes, or in

the absence of local codes, with the National Electric Code ANSI/

NFPA 70 - Latest Edition. Unit must be electri cally grounded in

conformance to this code. In Canada, wiring must comply with

CSA C22.1, Part 1, Electrical Code.

2. Two copies of the unit wiring diagram are provided with each unit.

One is located in the side access control compartment and the

other is supplied in the literature packet. Refer to this diagram for

all wiring connections.

3. Make sure all multi-voltage components (motors, transform ers,

etc.) are wired in accordance with the power supply voltage.

4. The power supply to the unit must be protected with a fused or

circuit breaker switch.

5. The power supply must be within 5 percent of the voltage rating

and each phase must be balanced within 2 percent of each other.

If not, advise the utility company.

6. External electrical service connections that must be installed

include:

a. Supply power connection (115, 208, 230, 460, or 575 volts).

b. Connection of thermostats, or any other accessory control

devices that may be supplied (24 volts).

InsTAllATIon - eleCTrICAl ConneCTIons

Table 17.1 - Propeller unit model PTC operating electrical data

➀

Table 17.2 - Blower model BTC motor

Amp

draw

Table 17.3 - Blower model BTC Control

Circuit Amp draw

➁

Table 17.4 - Blower model BTC

Accessory Transformer size (kvA)

➂

➀

Amp draw data shown is operating amp

draw at incoming power. For units that

use a field installed accessory step-down

transformer as noted, the amp draw

shown is the primary side operating amp

draw. For sizing of circuit protection for

equipment with transformers, please refer

to the National Electric Code.

➁

For BTC models, add the Motor Amp

Draw and Control Circuit Amp Draw to get

the Total Unit Amp Draw.

➂

Transformers for blower models are

typically smaller than those used for

propeller models, as the transformer is

not needed for the blower motor.

noTe: All units with supply voltage 208V and greater must use a

field installed step-down transformer, available as a separate

accessory. Refer to Tables 17.1 and 17.4 for additional

information on the required transformer.

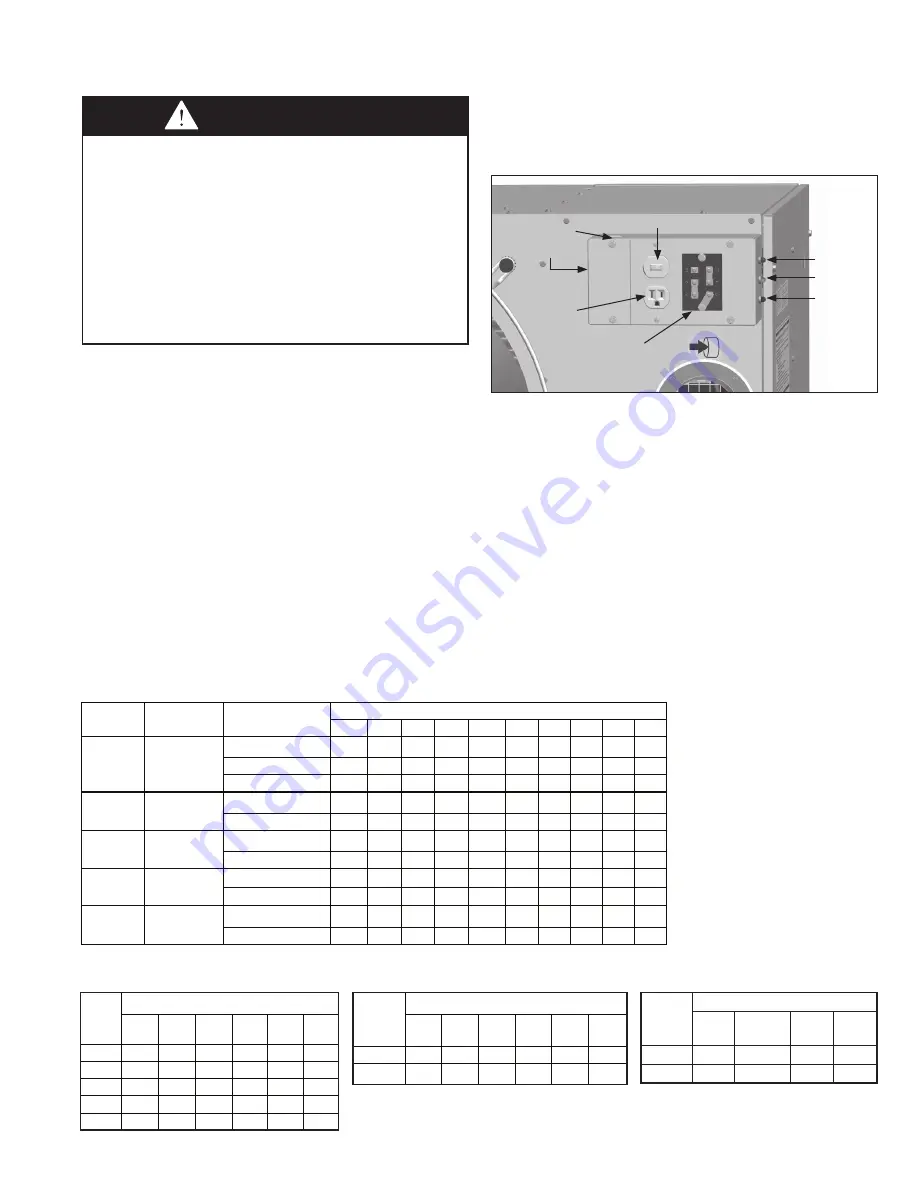

7. Refer to Figure 17.1 for the junction box wiring entry location.

8. All supply power electrical connections are made in the junction

box compartment of the unit. The low voltage (thermostat and

accessory control devices) can be wired to the terminals on the

junction box.

Additional notes for the Condensate Pump outlet:

9. The condensate pump outlet supplied with this unit is intended for

use with a condensate pump with operating amps not to exceed

2 Amps.

10. The condensate pump cutlet can be used as a service outlet. To

be used as a service outlet, the disconnect switch located above

the outlet must be in the OFF position to disable the unit heater

power and gas control circuits to prevent equipment damage.

When the unit is wired directly to a 115V power supply, the outlet

is rated for a maximum load of 20 amps at 115V. If this unit has

been provided with an accessory step-down transformer to 115V

from a higher supply voltage, ensure that the load plugged into

the outlet does not exceed 8A for 1.0kVA or 12A for 1.5kVA rated

transformers.

Supply Power

Conduit Entry

Knockouts

Unit On/Off Switch

Condensate

Pump Outlet

Terminal Board

for Low Voltage

Control Wiring

unit status

lights:

Green =

Power On

Amber =

Call for Heat

Blue =

Burner On

supply

voltage

Power

Code

model PTC sizes

55

65

85 110 135 156 180 215 260 310

115V

1 Phase

01 (115V)

m

otor Amps

2.20 2.20 2.20 4.60 4.60 4.60 4.60 7.00 8.80 8.80

Total Amps

4.35 4.35 4.35 6.75 6.75 6.75 6.75 9.15 10.95 9.85

Transformer kvA n/a

n/a n/a n/a

n/a

n/a n/a n/a n/a n/a

208V

1 or 3

Phase

01 (115V)

with

Transformer

Transformer kvA 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.50 1.50 1.50

208v Total Amps

2.41 2.41 2.41 3.73 3.73 3.73 3.73 5.06 6.05 5.45

230V

1 or 3

Phase

01 (115V)

with

Transformer

Transformer kvA 0.75 0.75 0.75 1.00 1.00 1.00 1.00 1.50 1.50 1.50

230v Total Amps

2.18 2.18 2.18 3.38 3.38 3.38 3.38 4.58 5.48 4.93

460V

3 Phase

01 (115V)

with

Transformer

Transformer kvA 0.75 0.75 0.75 1.00 1.00 1.00 1.00 1.50 1.50 1.50

460v Total Amps

1.09 1.09 1.09 1.69 1.69 1.69 1.69 2.29 2.74 2.46

575V

3 Phase

01 (115V)

with

Transformer

Transformer kvA

0.75 0.75 0.75 1.00 1.00 1.00 1.00 1.50 1.50 1.50

575v Total Amps

0.87 0.87 0.87 1.35 1.35 1.35 1.35 1.83 2.19 1.97

motor

HP

supply voltage

115v/

1ph

230v/

1ph

208v/

3ph

230v/

3ph

460v/

3ph

575v/

3ph

1

14.00 7.00 3.20 3.20 1.60 1.30

1-1/2 15.00 7.50 4.60 4.80 2.40 1.90

2

-

-

6.00 5.80 2.90 2.30

3

-

-

8.40 7.80 3.90 3.20

5

-

-

13.60 12.30 6.20 5.10

model

size

supply voltage

115v/

1ph

230v/

1ph

208v/

3ph

230v/

3ph

460v/

3ph

575v/

3ph

215-260 2.15 1.08 1.19 1.08 0.54 0.43

310

1.05 0.53 0.58 0.53 0.26 0.21

model

size

supply voltage

208v

3 ph

230v

1 or 3 ph

460v

3 ph

575v

3 ph

215-260 0.50

0.50

0.50

0.50

310

0.50

0.25

0.25

0.25

figure 17.1 - Power/Control Wiring