10-21

Chapter 10 COOLING SYSTEM

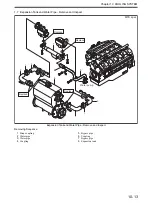

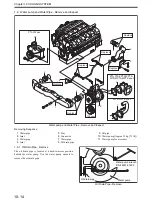

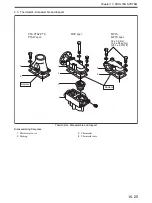

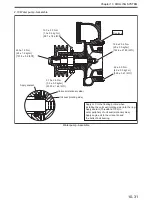

2.3 Tension Pulley - Disassemble and Inspect (Water pump side PTA2 spec)

Tension Pulley - Disassemble and Inspect (Water pump side PTA2 spec)

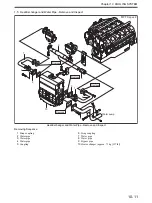

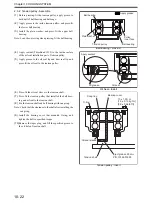

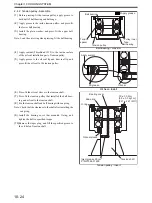

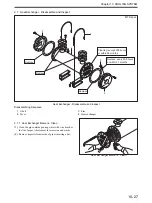

2.3.1 Tension Pulley - Inspect

Measure the bearing fit in tension pulley and on shaft. If abnormal wear or damage is shown, replace the bearing, pulley or ten-

sion bracket.

Belt groove wear

Replace

Rotation

Lip surface wear,

flaw, deterioration

Crack, flaw,

deflection of shaft,

oil hole clogging

PTA2 spec

1

2

3

4

5

6

7

8

9

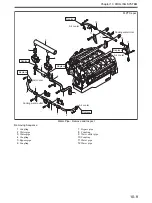

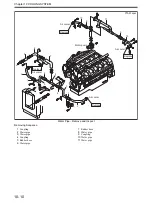

Disassembling Sequence

1

Bearing cover

2

Snap ring

3

Ball bearing

4

Plain washer

5

Ball bearing

6

Tension pulley

7

Oil seal

8

Oil seal sleeve

9

Bracket

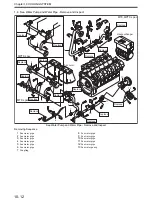

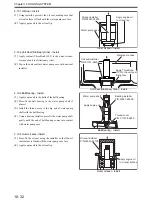

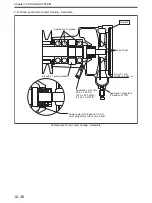

Item

Standard value

Standard value

Inside diameter of tension pulley bearing fit

ø90 [3.54]

89.972 to 89.994 mm [3.5422 to 3.5431 in.]

Bearing

Outside diameter

ø90 [3.54]

89.985 to 90.000 mm [3.5427 to 3.5433 in.]

Inside diameter

ø40 [1.57]

39.988 to 40.000 mm [1.5743 to 1.5748 in.]

Outside diameter of bracket bearing fit

ø40 [1.57]

39.984 to 40.000 mm [1.5742 to 1.5748 in.]

Summary of Contents for S12A2

Page 1: ...SERVICE MANUAL September 2010 Pub No 99269 20170 199269 20170 ...

Page 2: ......

Page 16: ......

Page 20: ......

Page 42: ......

Page 44: ......

Page 68: ......

Page 69: ...3 1 Chapter 3 SERVICE TOOLS 1 Special Tools 3 3 ...

Page 70: ......

Page 78: ......

Page 82: ......

Page 136: ......

Page 174: ......

Page 218: ......

Page 220: ......

Page 242: ......

Page 244: ......

Page 294: ......

Page 310: ......

Page 320: ......

Page 322: ......

Page 334: ......

Page 354: ......