5-17

Chapter 5 DISASSEMBLY OF BASIC ENGINE

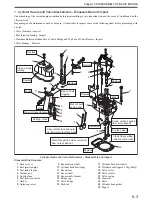

4. Cylinder Liner, Piston and Connecting Rod - Disassemble and Inspect

Understanding of the current engine condition before disassembling is very important to know the cause of trouble and do the

efficient work.

Depending on the maintenance work or purpose, it is desirable to inspect some of the following items before proceeding with

any job.

Piston Protrusion - Measure

Connecting Rod End Play - Measure

Cylinder Liner Inside Diameter - Measure

Cylinder Liner Flange Protrusion - Measure

Cylinder Liner, Piston and Connecting Rod - Disassemble and Inspect

12

11

10

9

8

7

6

5

4

3

2

1

Crack, oil hole clogging

Outer peripheral surface scratch,

crack, flaw, carbon deposit

Inner face wear,

flaw, discoloration

Inner and outer

peripheral

surface flaw,

seizure, peeling

Replace.

D

eformation, wear

Wear, flaw

Flaw

Serrated portion

wear, crack

Inner face scratches/wear,

outer peripheral O-ring

groove rust/cavitation

Disassembling Sequence

1

Connecting rod cap bolt

2

Connecting rod cap

3

Lower connecting rod bearing

4

Upper connecting rod bearing

5

No. 1 compression ring

6

No. 2 compression ring

7

Oil ring

8

Snap ring

9

Piston pin

10

Piston

11

Connecting rod

12

Cylinder liner (Approx 16 kg [35 lb])

Summary of Contents for S12A2

Page 1: ...SERVICE MANUAL September 2010 Pub No 99269 20170 199269 20170 ...

Page 2: ......

Page 16: ......

Page 20: ......

Page 42: ......

Page 44: ......

Page 68: ......

Page 69: ...3 1 Chapter 3 SERVICE TOOLS 1 Special Tools 3 3 ...

Page 70: ......

Page 78: ......

Page 82: ......

Page 136: ......

Page 174: ......

Page 218: ......

Page 220: ......

Page 242: ......

Page 244: ......

Page 294: ......

Page 310: ......

Page 320: ......

Page 322: ......

Page 334: ......

Page 354: ......