9-20

Chapter 9 LUBRICATION SYSTEM

2.10 Bypass Valve - Inspect

Inspect the bypass valve opening pressure. If limit is

exceeded, replace it with a new one.

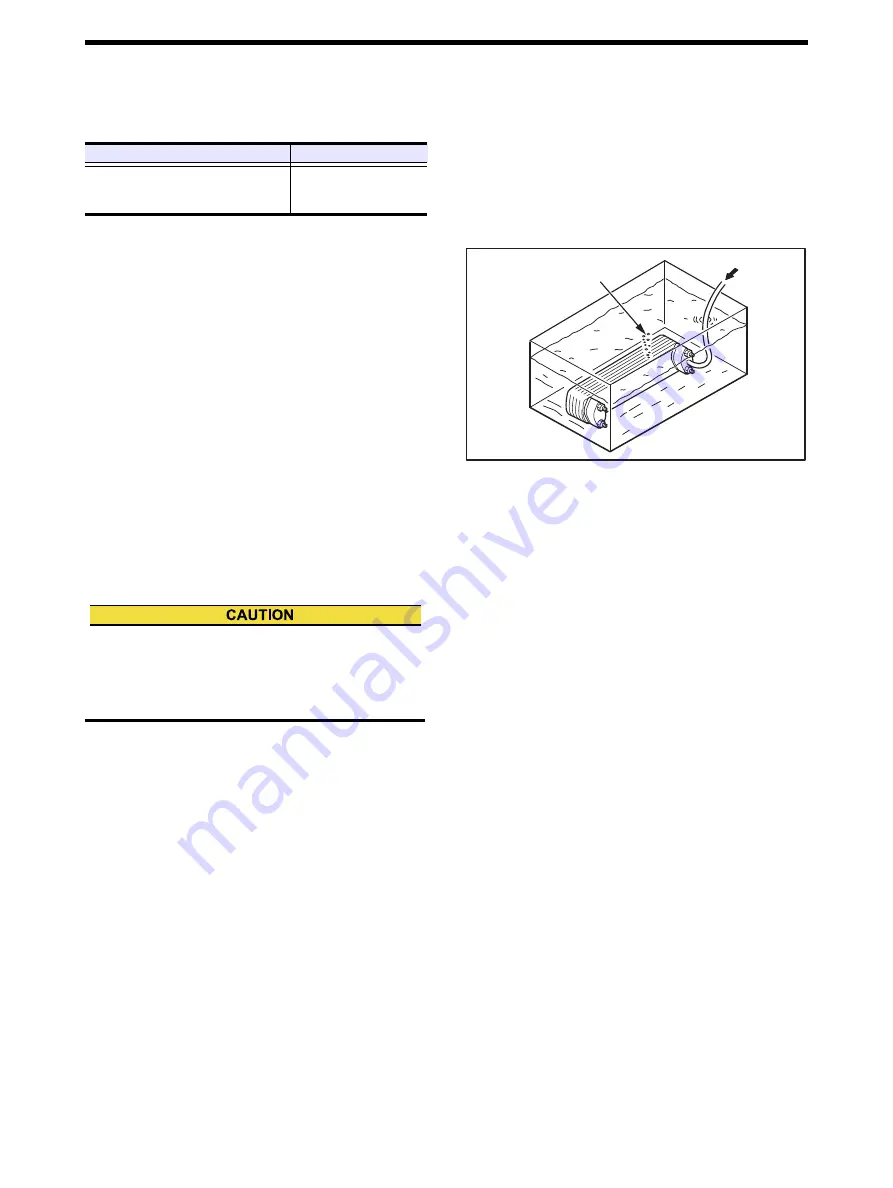

2.11 Oil Cooler - Inspect

Check the oil passages of element for flaws or cracks by

applying compressed air of 1.5 MPa {15 kgf/cm

2

} [217 psi].

If any leakage or damage is found, replace the element with

a new one.

Oil Cooler - Inspect

2.12 Oil Filter, Relief Valve and Oil Cooler - Assemble

To assemble, follow the disassembly sequence in reverse.

Thoroughly clean oil passages with wash oil, and dry the

cleaned parts with compressed air.

2.13 Oil Filter Cartridge - Install

(1)

Remove dust and contamination on oil filter cartridge

mating face.

(2)

Apply clean engine oil on oil filter gasket.

(3)

After the oil filter gasket contacts with base surface,

tighten the cartridge by 3/4 to 1 turn by hand.

(4)

Start the engine, and make sure that there is no fuel

leaks.

Item

Standard value

Bypass valve opening pressure

0.44 ± 0.05 MPa

{4.49 ± 0.51 kgf/cm

2

}

[64 ± 7 psi]

Air

Leak, flaw, crack check

(a) When installing oil filter cartridge, tighten it by

hand. (Do not use filter wrench.)

(b) Be careful not to dent or damage the surface of

cartridge.

Summary of Contents for S12A2

Page 1: ...SERVICE MANUAL September 2010 Pub No 99269 20170 199269 20170 ...

Page 2: ......

Page 16: ......

Page 20: ......

Page 42: ......

Page 44: ......

Page 68: ......

Page 69: ...3 1 Chapter 3 SERVICE TOOLS 1 Special Tools 3 3 ...

Page 70: ......

Page 78: ......

Page 82: ......

Page 136: ......

Page 174: ......

Page 218: ......

Page 220: ......

Page 242: ......

Page 244: ......

Page 294: ......

Page 310: ......

Page 320: ......

Page 322: ......

Page 334: ......

Page 354: ......