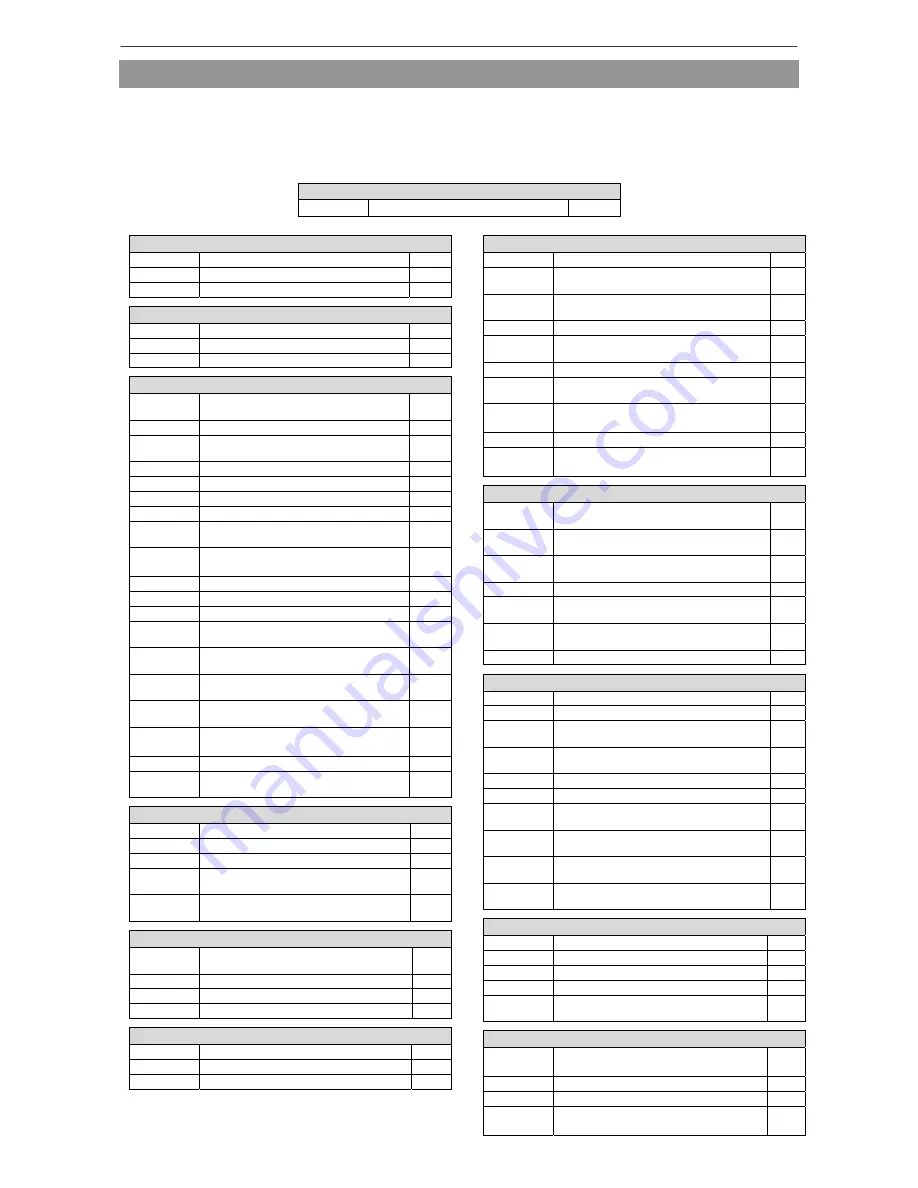

Program mode list

[17] Program mode list

Changing to the program mode

When using the LCD panel, refer to the section " Operation panel section[16] Program mode ". When using the 7-segment operation

panel keys, refer to pages " Control unit section[8]-3 to [8] -4".

* For item (*1), there is no LCD panel program mode item. Change to each mode using the 7-segment operation panel keys. Depending

on the item, the other LCD panel functions can be operated. (For example, [O1L] in the "output signal" item can be operated from the

"input/output setting mode".)

Table explanation

[

type

]

[ symbol ]

[ function name ]

[mode]

Wiper

WIP Wiper

ON/OFF

4(1)

W1

Wiper output (W) output start time

B33

W2

Wiper output (W) output time

B34

Slow start

S

Slow start speed

B43

SL

Slow start setting

B44

SLN

Number of slow start stitches

B45

Clamp

OST

Start/stop even if work holder is not

lowered

G40

RPT

Repeat sewing setting

G1

RP(1-8)

Work holder 1-8 repeat sewing setting

G(2-

9)

WHY

Work holder order of priority setting

G10

FSR

All cancel during step over operation

G11

1PD

1-pedal specification setting

G12

1T

1-pedal timer setting

G13

(1-8)A

Work holder 1-8 ON delay timer setting

G(14

-21)

(1-8)B

Work holder 1-8 OFF delay timer

setting

G(22

-29)

OFB

Number of Work holder division setting

G30

FN

Number of rated Work holder setting

G31

CF

Work holder sequence setting

G32

F21N

Valid Work holder number setting for

divided Work holder (OF1…OF4)

G33

F22N

Valid Work holder number setting for

divided Work holder (OF5…OF8)

G34

CF1

Work holder sequence setting for

divided Work holder (OF1…OF4)

G35

CF2

Work holder sequence setting for

divided Work holder (OF5…OF8)

G36

F4BN

Valid number setting of Work holder

blocks

G37

F4SN

Number of block steps setting

G38

AF2

Pneumatic type two stage work holder

selection

G39

Sewing area

ALC

Sewing area limit cancel

A1

XL

[X axis left side] area limit setting

X5

XR

[X axis right side] area limit setting

X6

YU

[Y axis back side] area limit

modification

X7

YD

[Y axis front side] area limit

modification

X8

Needle position

RU

Reverse run needle UP function after

thread trimming

B5

R8

RU reverse angle setting

B6

U8

Needle UP position stop angle

B7

D8

Needle DOWN position stop angle

B8

Bobbin winding

W

Bobbin winding speed

B46

WSM

Bobbin winding operation setting

B47

WT

Bobbin winding operation time

B48

Home position

HPM

Home position return method at HALT

A10

HPC

Home position return prohibit at power

ON

A11

HPF

Automatic home position return

operation prohibition

A12

HPK

Reset key setting

A14

2HS

Temporary stop method at secondary

home position

A15

FHP

Free home position usage method

A16

CHS

Home position correct selection at

sewing data read

A17

SHX

[X axis] limit sensor home position

return

X9

SHY

[Y axis] limit sensor home position return

X10

HPS

Setting for presser foot state of home

return operation after power ON

A13

HALT

STF

Feed data stop state at HALT switch

operation

A2

STN

Needle stop state at HALT switch

operation

A3

STS

Various output hold at HALT switch

operation

A4

ST2

HALT switch two-press operation

A5

STP

Power operation at HALT switch

operation

A7

STD

Work holder raise operation when

stopped with HALT code

A8

STL

Double-drop prevention after HALT

A9

Counter

CUP

Increment (UP) counter function

A21

CDN

Decrement (DN) counter function

A22

UCM

Increment (UP) counter setting value

clear method

A23

DCM

Decrement (DN) counter setting value

clear method

A24

PCM

Counter clear method at power ON

A25

CN

Number of stitches count function

A26

UCC

Increment (UP) counter count value

correction prohibit

A27

DCC

Decrement (DN) counter count value

correction prohibit

A28

USC

Sewing work with increment (UP)

counter

A29

DSC

Sewing work with decrement (DN)

counter

A30

Brakes

WBK

Weak brake setting

B1

BKM

Weak brake function setting

B2

BNR

Weak brake noise setting

B3

BKT

Brake time setting

B4

PW

Weak brake operation time during

presser bar lifting operation

X23

Presser foot

PD

Presser bar lifting timer 1 (lowering)

setting

B35

PU

Presser bar lifting timer 2 (rising) setting

B36

UW

Presser bar lifting timer 3 (rising) setting

B37

BPF

Setting of presser foot when baste is

sewn and the feed moves

B26

Summary of Contents for PLK-E Series

Page 2: ......

Page 13: ...Explanations of basic screens keys and operations 3 6...

Page 15: ...Stitching data type and writing No 4 1...

Page 21: ...Reading writing and erasing data floppy disk 5 5...

Page 26: ...Reading writing and erasing data internal memory 6 4...

Page 28: ...7 1...

Page 35: ...Creating simple stitching data 8 6...

Page 39: ...Methods of creating stitching data 9 3...

Page 44: ...Methods of creating stitching data 9 7...

Page 54: ...Methods of creating stitching data 9 15...

Page 58: ...Methods of creating stitching data 9 22...

Page 63: ...Methods of creating stitching data 9 26...

Page 68: ...Methods of creating stitching data 9 30...

Page 72: ...Methods of creating stitching data 9 33...

Page 75: ...Methods of creating stitching data 9 35...

Page 79: ...Methods of creating stitching data 9 38...

Page 86: ...Modification mode 12 5...

Page 89: ...Modification mode 12 7...

Page 94: ...Modification mode 12 11...

Page 99: ...Modification mode 12 15...

Page 104: ...Modification mode 12 19...

Page 111: ...Modification mode 12 25...

Page 115: ...Modification mode 12 28...

Page 122: ...Modification mode 12 34...

Page 126: ...Modification mode 12 37...

Page 133: ...Modification mode 12 43...

Page 138: ...Modification mode 12 47...

Page 143: ...Modification mode 12 51...

Page 148: ...Modification mode 12 55...

Page 155: ...Data conversion mode 13 6...

Page 158: ...Data conversion mode 13 8...

Page 162: ...Data conversion mode 13 11...

Page 166: ...Data conversion mode 13 14...

Page 169: ...Data conversion mode 13 16...

Page 179: ...Data conversion mode 13 25...

Page 204: ...Program mode 16 5...

Page 205: ...Program mode 16 6...

Page 208: ...Program mode list 17 2...