Page 6

MODEL: WT-42313 / WT-42413

SAFETY PRECAUTIONS

NOTICE:

Observe all cautions and safety related notes located inside the receiver cabinet and on the

receiver chassis.

WARNING:

1.

Operation of this receiver outside the cabinet or with the cover removed presents a shock hazard

from the receiver's power supplies. Work on the receiver should not be attempted by anyone who is

not thoroughly familiar with the precautions necessary when working on high voltage equipment.

2.

Do not install, remove or handle the picture tubes in any manner unless shatterproof goggles are

worn. People not so equipped should be kept away while the picture tube is being handled. Keep

the picture tube away from the body while handling.

3.

When service is required, observe the original lead dress. Extra precaution should be taken to

assure correct lead dress in the high voltage area. Where a short-circuit has occurred, replace those

components that indicate evidence of overheating.

X-Radiation warning

The surface of the cathode ray tubes (CRTs) may generate X-Radiation, so take proper precautions when servic-

ing. It is recommended that a lead apron be used for shielding while handling the CRT. Use this method if

possible.

When replacing the CRTs, use only the designated replacement part since it is a critical component with regard to

X-Radiation. High voltage must be set as prescribed under the section titled Electrical Adjustments.

Leakage current check

Before returning the receiver to the customer, it is recommended that leakage current be measured according to

the following methods.

1. Cold Check

With the alternating current (AC) plug removed from the AC source, place a jumper across the two AC plug

prongs. Connect one lead of an ohm meter to the AC plug and touch the other lead to each exposed metal

part (i.e. antennas, handle bracket, metal cabinet, screw heads, metal overlay, control shafts, etc.), particu-

larly any exposed metal part that has a return path to the chassis. The resistance of the exposed metal parts

having a return path to the chassis

should be a minimum of 1Mega Ohm

. Any resistance below this value

indicates an abnormal condition and requires corrective action.

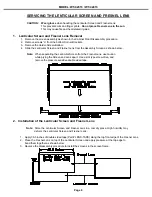

2. Hot Check ...Use the circuit shown below to perform the hot check test.

1. Keep switch S1 open and connect the receiver to the measuring circuit. Immediately after

connection, and with the switching devices of the receiver in their operating positions, measure

the leakage current for both positions of switch S2.

2. Close switch S1, energizing the receiver. Immediately after closing switch S1, and with the

switching devices of the receiver in their operating positions, measure the leakage current for both

positions of switch S2. Repeat the current measurements of items 1 and 2 after the receiver has

reached thermal stabilization.

The leakage current must not exceed 0.5 milliampere (mA).

Summary of Contents for WT-42313

Page 2: ......

Page 11: ...MODEL WT 42313 WT 42413 Page 11 PCB Locations Major Parts Locations ...

Page 53: ...MODEL WT 42313 WT 42413 Page 53 POWER SUPPLY ...

Page 54: ...MODEL WT 42313 WT 42413 Page 54 VIDEO COLOR ...

Page 55: ...MODEL WT 42313 WT 42413 Page 55 SYNC SIGNAL PATH ...

Page 56: ...MODEL WT 42313 WT 42413 Page 56 DEFLECTION HV ...

Page 57: ...MODEL WT 42313 WT 42413 Page 57 HV REGULATION ...

Page 58: ...MODEL WT 42313 WT 42413 Page 58 X RAY PROTECT ...

Page 59: ...MODEL WT 42313 WT 42413 Page 59 SOUND SIGNAL PATH ...

Page 60: ...MODEL WT 42313 WT 42413 Page 60 CONVERGENCE ...

Page 61: ...MODEL WT 42313 WT 42413 Page 61 CONTROL CIRCUITRY ...