5 WIRING

5.2 External Wiring

29

5

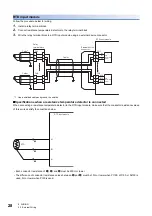

To use a connector/terminal block converter module

A connector/terminal block converter module for MELSEC-Q series temperature input module can be used with a temperature

input module. This section shows the examples of external wiring when a connector/terminal block converter module is used.

Thermocouple input module

Use the connector/terminal block converter module for the Q68TD-G-H02(H01). Wire the modules as shown below.

*1 Connect the cold junction compensation resistor (RTD) when With cold junction compensation (0) is set to 'Cold junction compensation

with/without setting' (Un\G298).

*2 Ground the shields.

*3 The RTD- and RTDG are connected in the connector/terminal block converter module. Therefore the connection of RTD- and RTDG at

the terminal block is not required.

Product name

Model

Remarks

Contact

Connector/terminal block converter module

FA-LTB40TDG

Your local Mitsubishi Electric sales office or

representative

Dedicated cable

FA-CBL05Q68TDG

Cable length: 0.5m

FA-CBL10Q68TDG

Cable length: 1.0m

FA-CBL20Q68TDG

Cable length: 2.0m

FA-CBL30Q68TDG

Cable length: 3.0m

RTD+

RTD-

RTDG

RTD

Dedicated cable

Shield

*2

Shield

*2

Connector/terminal block

converter module

Compensation

lead wire

Shield

*2

CH1+ (terminal 1)

CH1- (terminal 2)

RTD+ (terminal 38)

RTD- (terminal 40)

*1

Module internal wiring

*3

Thermocouple

input module

Summary of Contents for R60RD8-G

Page 2: ......

Page 14: ...12 MEMO ...

Page 18: ...16 1 PART NAMES MEMO ...

Page 24: ...22 4 PROCEDURES BEFORE OPERATION MEMO ...

Page 41: ...7 OFFSET GAIN SETTING 7 1 Setting Procedure 39 7 13 Click Yes button ...

Page 47: ...I 45 MEMO ...

Page 51: ......